Ferndown: Difference between revisions

No edit summary |

No edit summary |

||

| Line 20: | Line 20: | ||

<blockquote><q>Over the years I got to know a lot of retailers James Barber became good friends and he would buy most of my production in the early days, Eddy Kolpin in LA, I knew from his visits to Dunhill’s as a PPD, he contacted me and wanted to come over to the workshop to chat, within a week he came over and he became my USA agent, Dolly and I went to a lot of the RTDA’s in the USA and sales went through the roof. At times we were making 1200 pipes a year all handmade hand cut mouthpieces and as Dolly was so good at her job in finishing the result was the Ferndown that is sold today, after some time we decided to make all the pipes with Silver Bands, cap bands, spigots, and army mounts. That’s when I stopped making any work for other pipe makers, so we could concentrate on our own work.</q> Les Wood. Jan, 2020.</blockquote> | <blockquote><q>Over the years I got to know a lot of retailers James Barber became good friends and he would buy most of my production in the early days, Eddy Kolpin in LA, I knew from his visits to Dunhill’s as a PPD, he contacted me and wanted to come over to the workshop to chat, within a week he came over and he became my USA agent, Dolly and I went to a lot of the RTDA’s in the USA and sales went through the roof. At times we were making 1200 pipes a year all handmade hand cut mouthpieces and as Dolly was so good at her job in finishing the result was the Ferndown that is sold today, after some time we decided to make all the pipes with Silver Bands, cap bands, spigots, and army mounts. That’s when I stopped making any work for other pipe makers, so we could concentrate on our own work.</q> Les Wood. Jan, 2020.</blockquote> | ||

To many pipe dabsters, Les Wood's pipes embody the revival of great English pipe making initiated by Ashton in the early 1980s. The high grade | To many pipe dabsters, Les Wood's pipes embody the revival of great English pipe making initiated by Ashton in the early 1980s. The high-grade Italian and Spanish plateau he prefers is oil-cured in the tradition of both Dunhill and Ashton. The pipes are renowned for their pleasant, slightly nutty flavor and remarkable smoking characteristics. They feature impeccable craftsmanship extending to very good stem/bit work, though many pipes are often a bit heavier. The hallmark of his work, of course, is the excellent silver work. Almost all of his pipes feature rings or ferules for spigot stems. Grading is by finish: "Bark" (ca. 90%, sandblasted dark brown and black), "Antique Bark" (tan sandblasted), "Reo" (brown and red, smooth), "Root" (orange, smooth), and "Tudor Root" (orange and brown smooth) and by size (one to four stars). He also designates straight grains with SG. | ||

Les Wood's metalwork is frequently in demand with other brands like Ashton or Comoy´s and most recently with Bentley for the [[John Aylesbury]] POY 2008. | Les Wood's metalwork is frequently in demand with other brands like Ashton or Comoy´s and most recently with Bentley for the [[John Aylesbury]] POY 2008. | ||

<center><gallery mode="nolines" widths=320px heights=250px perrow= | <center><gallery mode="nolines" widths=320px heights=250px perrow=4 caption="Directly from Mr. Les Wood's workshop."><center> | ||

83523525_589127448302375_614011552588103680_n.jpg | |||

83888643_198987081504021_3311074426895728640_n.jpg | |||

83930919_611845529634823_1129960858550534144_n.jpg | |||

83932416_497208880982522_462213535603097600_n.jpg | |||

84182449_1003955723305817_1164165445519933440_n.jpg | |||

84359394_1089696428032826_2969227560216428544_n.jpg | |||

84415722_3452619364846310_1264263923255738368_n.jpg | |||

84648757_173160074024390_734517150819024896_n.jpg | |||

</gallery> | </gallery> | ||

<br> | |||

<div class="separator" style="clear: both; text-align: center;"></div> | |||

---- | |||

{| class="wikitable" style="margin: left;" | |||

|<center>'''About Workshop'''</center> | |||

|} | |||

We bought the briar from Italy and Spain, one is mush denser that the other I like the Spanish briar it is lighter and Dolly would make the Roots look like glass with only a natural vanish, all the pipes were finished with the same varnish, the bark finish on the bowl is put on by Dolly by hand, one slip and you have a problem that’s one job that need to be seen to see how done. | |||

In the work shop we have our own jobs I turn the bowls and fit the rod vulcanite and shape it to the pipe, if I had time I would pumice them or Dolly would do it she took over from there, I only got the pipe back when it was stained and finished, ready for me to put the silver on, each silver band is fitted to each pipe as an individual made to fit that pipe only. | |||

We then stamp it and engrave the M/P with LJS, | |||

<br> | |||

<div class="separator" style="clear: both; text-align: center;"></div> | |||

---- | |||

[[File:R&L-Ferndown.jpg|thumb|center|600px|Ferndown Bark, Antique, courtesy [http://www.racineandlaramie.com/ Racine & Laramie Tobacconist]]] | [[File:R&L-Ferndown.jpg|thumb|center|600px|Ferndown Bark, Antique, courtesy [http://www.racineandlaramie.com/ Racine & Laramie Tobacconist]]] | ||

| Line 43: | Line 64: | ||

File:FerndownRoot04.jpg | File:FerndownRoot04.jpg | ||

File:FerndownRoot05.jpg | File:FerndownRoot05.jpg | ||

File:FerndownRusticatedBulldog.jpg | |||

File:10-5063.jpg | |||

File:10-5065.jpg | |||

File:FERNDOWN BARK 01.jpg | |||

File:FERNDOWN BARK 02.jpg | |||

File:LES WOOD.jpg | |||

84632330_202981674119015_5498504010937663488_n.jpeg | |||

84036295_1025062521193689_203665382081298432_n.jpg | |||

</gallery> | </gallery> | ||

<font size="1">Photos by Chance Whittamore</font> | <font size="1">Photos by Chance Whittamore</font> | ||

Revision as of 15:58, 5 February 2020

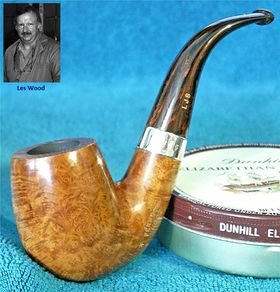

Leslie "Les" John Wood worked for Dunhill for 19 years. His last position was a master silversmith. Following his tenure with Dunhill, Les formed his own brand, L. & J.S. Briars together with his wife Dolly in 1978. Les Wood follows Sasieni, the first ex Dunhill worker to start their own enterprise, and he was followed by William John "Ashton"-Taylor.

I started working at Dunhill’s in March 1963, in the silver mounting department working under Jack Spriggs he left the firm after I had been there for 2 years, and I took over the department, at that time I worked alone it was only when the department was relocated to the top floor that the increase of pipes that needed mounting we took on a trainee’s. After 19 years I was asked if I would buy the machinery and move out of the factory and set up on my own, so off I went, with me I took the staff that worked with me at that time, Robert Morris was the best, he could mount anything, he now has his own jewellery retail shop and makes some really nice handmade jewellery from his shop at Whitstable in Kent.Les Wood. Jan, 2020.

I worked on Dunhill’s pipes from 1980/81 and soon built up a reputation as the firm to send you mounting to, as time went on and Dolly left Dunhill’s we decided to start to turn our own bowls and make our own pipes under the name of my house.

Due to diffuse worldwide rights to certain names, he sold his earlier pipes as " L.&J.S Briars", "Ellwood", "Les Wood" or "L. Wood". The average of presently 1500 - 2000 pipes a year are sold as "Ferndown" — named for the mansion he lives in - in the UK and US, but as "L. Wood" pipes in Germany.

Over the years I got to know a lot of retailers James Barber became good friends and he would buy most of my production in the early days, Eddy Kolpin in LA, I knew from his visits to Dunhill’s as a PPD, he contacted me and wanted to come over to the workshop to chat, within a week he came over and he became my USA agent, Dolly and I went to a lot of the RTDA’s in the USA and sales went through the roof. At times we were making 1200 pipes a year all handmade hand cut mouthpieces and as Dolly was so good at her job in finishing the result was the Ferndown that is sold today, after some time we decided to make all the pipes with Silver Bands, cap bands, spigots, and army mounts. That’s when I stopped making any work for other pipe makers, so we could concentrate on our own work.Les Wood. Jan, 2020.

To many pipe dabsters, Les Wood's pipes embody the revival of great English pipe making initiated by Ashton in the early 1980s. The high-grade Italian and Spanish plateau he prefers is oil-cured in the tradition of both Dunhill and Ashton. The pipes are renowned for their pleasant, slightly nutty flavor and remarkable smoking characteristics. They feature impeccable craftsmanship extending to very good stem/bit work, though many pipes are often a bit heavier. The hallmark of his work, of course, is the excellent silver work. Almost all of his pipes feature rings or ferules for spigot stems. Grading is by finish: "Bark" (ca. 90%, sandblasted dark brown and black), "Antique Bark" (tan sandblasted), "Reo" (brown and red, smooth), "Root" (orange, smooth), and "Tudor Root" (orange and brown smooth) and by size (one to four stars). He also designates straight grains with SG.

Les Wood's metalwork is frequently in demand with other brands like Ashton or Comoy´s and most recently with Bentley for the John Aylesbury POY 2008.

- Directly from Mr. Les Wood's workshop.

We bought the briar from Italy and Spain, one is mush denser that the other I like the Spanish briar it is lighter and Dolly would make the Roots look like glass with only a natural vanish, all the pipes were finished with the same varnish, the bark finish on the bowl is put on by Dolly by hand, one slip and you have a problem that’s one job that need to be seen to see how done.

In the work shop we have our own jobs I turn the bowls and fit the rod vulcanite and shape it to the pipe, if I had time I would pumice them or Dolly would do it she took over from there, I only got the pipe back when it was stained and finished, ready for me to put the silver on, each silver band is fitted to each pipe as an individual made to fit that pipe only. We then stamp it and engrave the M/P with LJS,

- Ferndown Root – 2 Star, courtesy Dennis Dreyer Collection

Photos by Chance Whittamore

- Ferndown Premier Sandblast (Les Wood & Michael Parks Collaboration) – 2 Star, courtesy Dennis Dreyer Collection

Photos by Chance Whittamore

Contact Information: