Fe-Ro

From Pipes, Artisans and Trademarks, by Jose Manuel Lopés'

Fe-Ro is an Italian brand created in 1949 by artisan Federico Rovera. and today also involving his daughter and son-in-law. The company is in Oltrona al Lago (Varese). Usual stamp: Fe.Ro. Pipe / Varese / Made in Italy

- See also Rovera

From the US Website: http://www.fero-usa.com/ :

Northwest of Milan, between Lake Varese and the highest mountain in Italy,Sacro Monte, lies the city of Varese, home of the Federico Rovera pipe factory. Brothers Federico, Francesco, Cornelio, and Carlo started manufacturing pipes in 1911. In 1949, Federico with the help of his sons founded Figli di Federico Rovera, which is currently the second largest pipe manufacturer in Italy. It is still a family owned business, run by Marina Rovera-Gazzaniga and her husband Enos Gazzaniga.

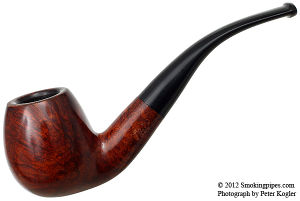

The factory’s production consists of pipe brands manufactured for well known names in the trade throughout Europe. Pipes imported to the USA carry their own brand name, Fe.Ro, an acronym of the founder’s name - Federico Rovera. They also manufacture related plastic articles, such as nylon tenons and mouthpieces, crystal pipe filters, cigarette and cigar holders, pipe rests and others. Part of the production is devoted to olive wood pipes.

Central Italian briar from the Tuscany region is used exclusively in their pipe production. Briar burl is a part of the white heath tree. It grows between the roots and the above ground tree. Burls harvested for Fe.Ro pipes must be 50 or more years old. They are cut into blocks, then boiled in water for up to 20 hours. This process removes all sap, resin, acid and other flavor distorting constituents.

Over the course of years, the supply of briar from various regions changes characteristics. Central Italian briar, at present, has richer grain than briars harvested in other parts of the country. While smoking characteristics may be the same regardless of grain, it is the visual and esthetic properties of the end product that prompt the Roveras to keep making a bigger initial investment in raw materials in order to have a superior finished product.

Once the blocks arrive at the factory, they are placed in the drying warehouse for a minimum of six months. They are air dried as opposed to kiln or oven drying used by some of the other manufacturers. This time consuming process results in a sweeter, dryer, better smoking pipe in general.

Grading of raw briar blocks is done to internationally recognized standards. There are 3 main classes with 2 subcategories and 5 size groups. Fe.Ro uses only high grade (Extra) blocks. Further grading takes place internally during the manufacturing process. This means that even a less expensive pipe by Fe.Ro carries the heritage of a high grade briar.

Turning a raw block of briar into a finished pipe involves between 40 to 50 steps, depending on the finish. The block in the hand of a pipe maker undertakes a long journey through a variety of working tools.

These processes involve turning, wood shaping, drilling, tooling, sanding, and staining. Even the mouthpiece has to be shaped to fit each individual pipe. All of the “Extra” grade pipes are finished using Brazilian Carnauba wax. It has a deeper and more permanent gloss than bee’s or other waxes.

The employees are accomplished in the skills required for creating a pipe from beginning to end. The factory uses not only some proprietary tools designed and created on site, but also implements certain proprietary components such as nylon tenons and color matched mastics. This combination of quality and looks delivers a superior product available only from Figli di Federico Rovera.

Contact Information:

US Distributor's Website: http://www.fero-usa.com/ Fe-Ro - Figli di Federico Rovera s.r.l. Fe-Ro - Figli di Federico Rovera s.r.l. Via C. Rovera 51 21026 Oltrona al Lago (Varese / Lombardia) Italy Phone: +39 0332 743271 E-mail: info@fe-ro.com Website: Fe-Ro