Metal Lathe

The metal lathe can play a huge role in pipe making. If large enough, it can be used for stummels as well as stems. Many pipe makers have both a metal lathe, and a wood lathe. Others have only one or the other, and still others have multiple metal lathes set up for different procedures. For a complete description of the metal lathe and it's various modes of operation, see the (Wikipedia link).

The main advantage of metal lathes over wood lathes is how precisely they can be used. This precision is achieved through the tool carriage and cross slide, more rigidity, and closer tolerances when manufactured. The tool carriage and cross slide moves the cutting tools precisely, and can maintain nearly any angle relative to the work being cut. This is a huge advantage when cutting tenons for stems, for example.

Full size metal lathes

For the sake of pipe making, I would call any lathe 9"x20" or larger to be full sized. This first number refers to the swing over the bed (or sometimes the tool carriage). This means it is possible for a 9" diameter work piece to swing over the bed, so the actual distance between the chuck center and the bed is actually slightly more than 4.5". The second number is the length of material that will fit between the chuck in the headstock, and the center in the tail stock. Many established pipe makers look for older lathes, such as those made by Atlas, Clausen, some older Sears models (these were all made by Clausen), Logan, Ward, and South Bend. The UK and the rest of Europe have many fine old lathes kicking around too (particularly Myfords, and for larger work, Colchesters).

The Chinese 9x20

For those not yet fortunate enough to find a quality older lathe, the new Chinese made 9" x 20" lathes are an affordable and workable option for many of us. Almost all the Chinese lathes are made in the same factory, and aside from the nameplate of the importer, the finish and accessories included, perform about the same. Popular brands include Jet, Grizzly, Smithy and Harbor Freight. While often functional, they all need to be dis-assembled, cleaned and re-assembled with good lubricants, and sometimes improved hardware and bearings.

In addition to being excellent for stems, many pipe makers also use metal lathes for stummel work. The tool carriage and cross slide can be used to rough in stummel shapes, while using it freehand, sort of like the technique used for drawing with an "Etch a Sketch" children's toy. It is also possible to set up a wood lathe style tool rest on a`metal lathe, which allows the use of wood lathe tools to slide along the work. Using a Jacobs chuck in the tail stock allows for very accurate boring of the chamber, mortise, and air hole, as well as facing the shank. A good quality, 9x20 or larger metal lathe, properly set up, can give one all the advantages of the metal lathe as well as most of those of a wood lathe.

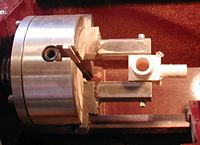

The lathe pictured is from Harbor Freight. It has been disassembled, cleaned, and re-fit with improved hardware, and a home brewed chuck, fashioned from a Grizzly 6" 4-jaw independent chuck, and modified after the J.T. Cooke style chuck that several tool makers are making for stummels (this home brewed version works just as well, but sure is not as pretty!). The locating pins allow for precisely positioning the air hole relative to the tobacco chamber. For bent pipes, two sets of locating holes are used. Drill the mortise on the shank axis, reposition the block for the air hole and tobacco chamber axis, drill the air hole, then loosen the block slightly, pivot the block on the pins, and re-tighten it to perfectly align the chamber with the air hole.

The 9x20 or most any other metal lathe is also a great tool for the Shape First method. For this method, the stummel is shaped prior to drilling and cannot be chucked, so the special bit is chucked into the headstock and the stummel is guided into the spinning bit.

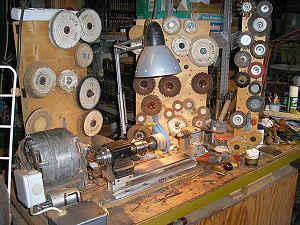

A full size metal lathe can also be used with for shaping, by chucking a sanding disk on an arbor into the headstock. This also works great for buffing wheels. A full size metal lathe comes about as close as you can get to a one tool pipe shop!

9x20 Mods and Off Site Links

The 9x20 can be a great machine, or a huge frustration. It is important to go through the cleaning, lubrication, and set up procedures described on the Yahoo group manuals (see bellow). Here are some important mods to consider which will help your lathe run smoothly and accurately, improve the cut, and improve its overall usability.

- Four bolt compound clamp. This is the very first mod that should be done. Places to purchase are: alansmachineworks.com, Sonny Harrison Machinery, and Little Machine Shop. It is also covered in the mod manuals in the Yahoo groups listed bellow, should you want to tackle it yourself.

- Get a Quick Change Tool Post (QCTP). This is a nice time saver. It eliminates the need for shimming individual tool bits, and enables you to use a 6" straight piece of square stock as a rest for the use of wood turning tools. Available where you got your lathe, or many on-line shops. A few of them are: Little Machine Shop, Harbor Freight, Grizzly

- The screw kit from Sonny Harrisson: This kit changes the lead screw in the compound from 5/16" to 7/16", and eliminates a lot of backlash. Sonny's website.

- Convert your tail stock to camlock-operation. This mod eliminates the need for using a wrench and allows adjusting the tail stock position by an easy lever action. See alansmachineworks.com, or the instructions for mods listed in the files section of the Yahoo groups if you want to do this mod yourself.

- Larger Cross Slide Handwheel: If you do a lot of facing work you will appreciate a larger cross slide handwheel. The stock handwheel is a little less than 2 3/8" OD. Increasing the OD to 3 1/8". The larger handwheel shown was turned from 1/2" aluminum plate and is actually just pressed over the original handwheel. Easy to build and really helps.

The headstock on the 9x20 uses a #3 Morse taper. This can accommodate a Jacobs chuck, which can be handy for certain operations, especially with the use of a keyless Jacobs chuck (no more hunting for the chuck key).

An excellent resource for information on the Chinese 9"x20" lathes can be found on Yahoo groups. The file sections include entire manuals, as well as thorough cleaning procedure, and various modifications and improvements: Main discussion site: http://groups.yahoo.com/group/9x20Lathe/ and a second group, http://groups.yahoo.com/group/9x20Lathe2/ for file section spill over.

Another good Mod site: Steve Beddair's 9x20 Lathe Page

Little Machine shop has a lot of tooling and information on the Mini Lathes:

'Custom pipe makers chucks, bits, and other specialized lathe tooling are available from:

Mini metal lathes

Chinese made

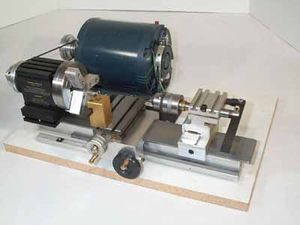

Like its larger counter parts, the Chinese made mini-lathes are all made in the same factory. Many are importing them under various names, but aside from length of the bed, color, nameplate, and tooling included, they are all about the same. They work very well once they are carefully cleaned up and re-assembled, sometimes with new hardware. The readily available 7"x12" size seems to be an excellent size for stem work. The 7"x10" can be just a little too short, but it is also possible to get extended beds for many of these lathes. Pictured bellow is the 7"x12" set up for stem work, with a three jaw, self centering chuck that most of them came with, and a Jacobs chuck that comes with some, and is an option with others.

The Taig

The basis for the Taig section of this article was written by Tyler Lane for his website, and is used by permission.

Tyler Lane writes, "I have a Taig, micro metal lathe, and micro it is! For those that are familiar with metal lathes, they would be socked at how small this lathe is. This is it greatest feature and it greatest weakness. Considering the price, this is a wonderful little tool. It is used to turn the tenons on stems to the precise diameter needed for a good fit between stem and stummel. It is also a key tool for doing stem inlay work.

A full-sized, metal lathe is the pipe makers pipe tool. If you have the funds, and want to skip to "the real deal" a nice metal lathe is the tool of choice. Not only can you turn and drill stummels on it, put you can turn the tenons for your stems as well. This is the main tool I would like to upgrade in my shop. A nice, used Atlas metal lathe from the 1950's or so, can be had for about $500 or $600 bucks, and would replace both my Delta Midi Lathe and my Taig.

Many people, like me when I was trying to figure out what tools I needed to start pipe making, do not know the difference between a metal and a wood lathe. The difference is mainly one of precision. I wood lathe has only a bar upon which to rest chisels that you operate by hand to shape the wood. A metal lathe, by contrast, has a tool carriage that precisely move a cutting bit along a constant, though adjustable, diameter. Both a wood lathe and a metal lathe will turn a variety of materials, they simply derive their name from the material that are most often used for.