Paul Tatum

Introduction

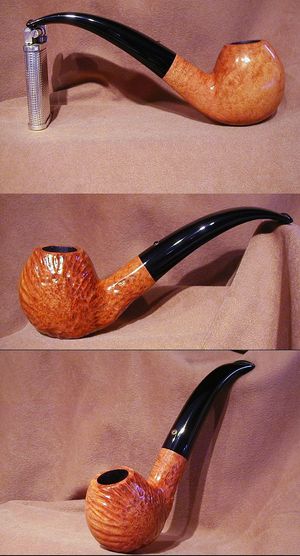

Paul Tatum is an American original. His pipes exhibit a unique personality and design sense with quirky, humorous and inventive interpretations of classic shapes and shapes that are uniquely his own. Coupled with that is Paul’s attention to the nuance of surface detail. The engineering of Paul’s pipes is exceptional, which should come as no surprise since Paul is an engineer.

Paul’s stem work is equally unique. He hand pours his stems. Where else are you going to find flames running along the length of the stem?

Paul Tatum pipes don’t often come on the market, as he stopped making pipes several years ago. On those rare occasions that a Paul Tatum pipe comes up for sale it is quickly snapped up by knowledgeable collectors. Here’s hoping that Paul Tatum will return to the making of his fine smoking pipes.

In Paul’s own words

Born in Atlanta GA, moved to Winston Salem North Carolina at age 11 and currently reside in Alabama. I've always been interested in how things work, building things and taking things apart. I loved it when an appliance broke when I was a kid, because that meant I got to fish it out of the trash can and take it apart to see how it worked.

My interest in pipes began after reading Lord of the Rings, back in the early 80's. When I was 18 I bought a $40 churchwarden and some cherry tobacco from the Tinder Box at Hanes Mall. While I was there I remember being fascinated by the meerschaum pipes.

This was the beginning of a long relationship with that Tinder Box, and I am still friends with a now retired tobacconist from the shop. As I bought pipes I was steered toward Dunhill by my friend. I think his interest was more in the historical value of the brand (he studied history in college) and less on the artistic value of the woodcarving.

As my collection grew I added a Dunhill now and again, but did a lot of experimenting with various carvers. I grew to admire the skill of some pipe makers and found that I really enjoyed the artisan-crafted pipes for the amount of time and care put into making them. I began to look at how the pipes were made and what contributed, in my opinion, to a good smoking pipe.

I didn't personally study with anyone in any formal way. I learned a lot from guys at pipe shows and the Internet. I read books. I guess the most interaction I had was with Trever (Talbert). He is certainly on a different level than I am, but our development as pipe makers tracks fairly closely, with me always being a step or two behind him in product. Of course, I never was really on the same plane as he from an artistic standpoint. We both explored the mechanics of what we thought was a good pipe from a smoking perspective at relatively the same time. We had a lot of discussion and I was able to smoke a lot of his test pipes and work through various manufacturing techniques with him.

So I suppose you could say that I learned second hand from a lot of the people Trever studied with before his move to France. From the beginning we were both in the camp of a more open draw for the airway. He pulled on his HVAC experience and I pulled on my engineering knowledge (in work at the time) of fluid mechanics and how warm, moist gasses behave when flowing through a passage of a given geometry. Between that and the body of knowledge on the Internet we formulated our own recipe for what we liked best in the airway of a pipe. We wanted cool smoke, less moisture build up and an easy draw that allowed the tobacco to remain lit at as low a temperature as possible. I can't say that there was any real science in what we came up with, but I think it works. I always thought it would be useful to do a full fluid dynamics analysis on pipe smoke, but I don't really like the subject and it would seem too much like work. Did I mention I am extremely lazy?

I enrolled in school at North Carolina A&T State University in Greensboro NC as a mechanical engineering student. In the mean time my shop equipment was good enough to start the pipe business so I crunched some numbers based on my skill and ability and came up with a figure that I needed to hit in order to make a humble living with pipe making. I went to school in the mornings, scheduled the earliest classes I could find, and made pipes and tampers in the afternoons. Since my commute to school was 45 miles one way, I needed a place to hang out in between classes, so I found a home at the Pipe and Pint. Larry Christopher was one of my finest critics and he helped me improve my skills. Between him and Trever I had a couple of good opinions to help guide my carving eye. As my skills increased I slowly moved away from tampers and focused on pipes. By 2004 I was primarily making pipes, but still did a few tampers.

I graduated from school in 2006 with an engineering degree and a job offer at the Marshall Space Flight Center as a structural designer. We moved to AL in 2006 and I poured all of my creative energy into designing components for the Ares I rocket, International Space Station and various smaller space flight projects. Today I am a flight controller for the Space Station. I'm one of the guys who work with the astronauts from the ground to help them work with science payloads while on orbit. I've made three pipes since I moved to AL. People say I am now a retired pipe maker, but I want to think I am just on extended hiatus.

My pipe collection consists of 50% straight billiards. In my mind they are the perfect example of a functional pipe, and a well executed billiard is a beautiful display of symmetry and proportion. I think if one applies the Golden Ratio to the billiard he will find that the most perfect billiards adhere to those measurements. The proportions are beautiful when executed and offensive when missed. Having said that, billiards are probably the least exciting pipes on the planet. I wanted to create unusual pipes, or pipes that flew in the face of tradition.

Rustication and surface treatment

I also like pipes that break the convention and one area of focus was in organic finishes. I specifically liked rustication because in the pipe world the rusticated pipe is traditionally the stepchild with bad grain or a minor flaw that gets the quick and dirty "pile of nails" rusticating tool or some other mangling device that is easy to apply. The idea is to salvage the pipe with as little time input as possible and move on. I looked at the rustication process as an area where artistic ability could be applied. I took a lot of inspiration from Micoli by Robert Burns. I love the rustication on those pipes and view it as art incarnate. I adapted the style to a set of brass tampers once, and they were a real beast to make because I did do the rusticating in the brass with a Dremel and standard Dremel tools. I wore out a lot of tools on that project. Some people say working with a Dremel is not hand rustication but a power tool. I say try carving brass with a Dremel for six hours and tell me if your hands think it's work.

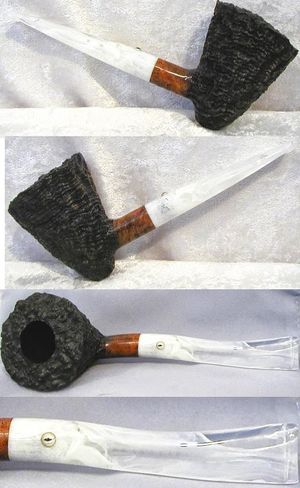

The Shoggoth pipes that I released for a few years in a row on HP Lovecraft's birthday went a step deeper with the detail in the rustication. A LOT of handwork with the Dremel. I'd start out with a large cutting tool, the 6" sanding disk, then use the Dremel 1/4" diameter ball cutter for the general shape, and work my way down in tool sizes until I got to 1/16 or smaller then do a light sandblast. The pipes were stained jet black and given a high gloss coat of natural shellac. The result was a glossy, amorphous blob that resembled what I thought a "Shoggoth" might look like. (See At The Mountains of Madness by HPL).

Another semi-rustication I created was called Egyptian Leather (read Mummy Skin) that was a combination of step down tool rustication, sand blast then buffing it smooth. All the rustication had to be done with an extremely light touch, and with a relation to the grain of the pipe in order to remove the tool marks with the buffing. Too much carving and the buffing wheel could not remove the tool marks, too little and it just looked like a bad carving.

- Examples of Egyptian Leather rustication

Another rustication technique that I liked was one that used the Dremel and a tool that looked like a skill saw blade, but 3/16" in diameter. The blade is about 1/16" thick. I would carve around the bowl with the blade, but be sure to maintain an orientation of about 30 degrees to the surface. The impact points would be placed as randomly as I could muster, but the angle of attack was as identical as I could muster. The result was a false grain to the carve, like feathers or fish scales. By applying a two tone stain, one shade to soak in the grooves and one coat wiped over the major surfaces, I was able to produce a kind of holographic effect, like your old 3D baseball cards that flashed a different scene when held at different angles. When viewed from the bottom the pipe would be one color, when viewed from the top another and from the side a graduated mix depending on the angle. I used this technique on the three or four cuttys I made.

One of my favorite pipes was the Broken Pipe I made as a gift for Larry Christopher at P&P. I saw this design in a book on antique pipes and decided to give it a try myself. I got a good deal of Internet kudos for that pipe, but it was not my own original design. While I did make some original items and techniques, a lot of what I created came from standing on the shoulders of great pipe makers from the past and present:

Stem work and tampers

Somewhere down the line I got in touch with a dentist in Wilmington NC who did woodworking on the side. He had a side business of pouring plastics for pen makers and had the whole setup of dyes and materials. I had the time to really explore the process. I also had the freedom of not having to drill a hole down the middle since tampers can be solid. I also was relatively certain no one would chew on them as well.

One issue I had when mixing things was bubbles in the mix. All the stuff was mixed by hand and I liked to add stuff like amber or tobacco, or bugs. It was all mixed in Dixie cups with Popsicle sticks. I figured out that if I mixed the stuff then put it in a pressure pot at 90 PSI it would compress the gas into solution, kind of like how carbon dioxide is compressed into soda. Once the plastic hardened inside the pot the gas was stable and bubbles gone. This was great for when I stirred in a spoon full of chopped tobacco or a live caterpillar.

Amber pebbles had roughly the same density so they suspended pretty well. Sometimes I'd drop BBs into the mix to streak the colors, like on Lemon Drop.

The flame stems were my favorite. I had to cut the flames in a partially cut stem, then press in the liquid plastic, then re-machine it. I have a tamper with three colors in the flames and each color represents that method done three separate times.

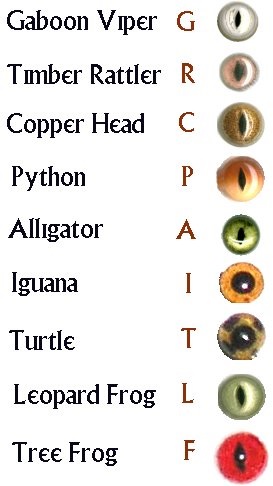

The stem logo

I wanted a grading system that was visible from a distance, and the taxidery eyes provided a way to do that. They were also very easy to apply, just a small touch to the stem with a 1/8" bit and I was ready to epoxy in the eye. I think I used the eyes on tampers before the pipes came along and it was just a natural move to incorporate them into the identity. I've always liked the weird eyeball jewelry when I was a kid, so working with taxidermy eyes was a given once my tampers got strange. I really don't recall any particular moment when I decided to use the eyes for stem logos.

- Gallery