Crawford Pipes: Difference between revisions

No edit summary |

No edit summary |

||

| (3 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

[[File:JerryCrawford.JPG|thumb|Jerry Crawford]] | |||

'''From the bio Jerry Crawford provided us:''' | '''From the bio Jerry Crawford provided us:''' | ||

'''Pipe maker Bio 2018''' | '''Pipe maker Bio 2018''' | ||

My love of pipes began many years ago as a child, my father had smoked a pipe and from | My love of pipes began many years ago as a child, my father had smoked a pipe and from watching him and old movies I always felt there was something interesting and special about pipes. Growing up I always enjoyed working with my father in his shop making cabinets, or furniture. My parents were both very resourceful and encouraged me to make or fix things and take classes on ceramics, metal working, wood working, leather crafts, plastics etc. during summer vacations. With a background in electronics and real estate which relied heavily on my attention to detail and creativity to be successful, the process of making pipes felt natural and gratifying to me from the start. | ||

watching him and old movies I always felt there was something interesting and special about | |||

pipes. Growing up I always enjoyed working with my father in his shop making cabinets, or | In the 1970s I began regularly smoking and collecting pipes. I always maintained and many times refurbished the estate pipes I bought, but sent them out for more extensive repair. In 2009 after getting a rare [[Comoy’s]] Blue Riband back from repair and saw the nomenclature had been completely removed, I committed to learning how to repair my own pipes. Around that same time I befriended [[Paul Hildebrand]], owner of Pipe Makers Emporium. Upon learning he not only repaired pipes but had also been making pipes for the past 10 years, I expressed my frustrations with repairs and my desire to learn to do them myself. | ||

furniture. My parents were both very resourceful and encouraged me to make or fix things and | |||

take classes on ceramics, metal working, wood working, leather crafts, plastics etc. during | |||

summer vacations. With a background in electronics and real estate which relied heavily on my | |||

attention to detail and creativity to be successful, the process of making pipes felt natural and | |||

gratifying to me from the start. | |||

After discussing some techniques used for repair, Paul invited me to spend a couple days working with him in his workshop, offering to show me the process of making pipes start to finish. In 2010 I made my first pipe and was immediately hooked. At that point the idea of just making repairs became secondary to making more pipes. | |||

After | After winning a billiard contest with only the 3 rd pipe I had ever made, I met [[Rainer Barbi]] who was one of the judges. With his encouragement and some valuable tips that I use to this day, I began buying more supplies and began tooling up to make more pipes. | ||

By 2012 I decided to work toward making pipes full time. In 2013 one of my pipes placed in the Greater Kansas City Pipe Clubs Carvers Contest. At that Kansas City show I met [[Premal Chheda]] and spent a week with him in his shop which helped me really fine tune my processes to better achieve the results I envisioned. In 2014, I was selected to make the pipe of the year for the Vancouver pipe club. | |||

After many years living in and around Phoenix Arizona my wife Viki and I relocated in March 2016 to Southern Oregon, finally realizing a dream to have a place with a shop in the woods. Some 40 miles south of me is home to a good friend and pipe maker [[Brad Pohlmann]] who has graciously shared his time and workshop on a regular basis for the past 2 years. Working with Brad and Silver has not only been inspiring but has helped me achieve my goals as a pipe maker to create pipes as I envision them, sometimes even better. | |||

and | |||

All of the pipes I craft are made using the best Italian briar available from the most vetted cutters. Each stem is hand cut with integral tenons, from the highest quality German Ebonite rod stock with the exception of an occasional Bakelite or Lucite material. Special attention is always given to creating an open and unrestricted draw and features my signature funneled opening at the button. | |||

Each pipe is hand crafted individually using time honored pre drilling or freehand techniques using the highest of tolerances to promote the superior smoking characteristics that have become synonymous with [[Crawford Pipes]]. | |||

== Gallery == | |||

<gallery widths=250px heights=185px mode="packed-hover" caption="More examples from Crawford Pipes, courtesy Smoker's Haven"> | |||

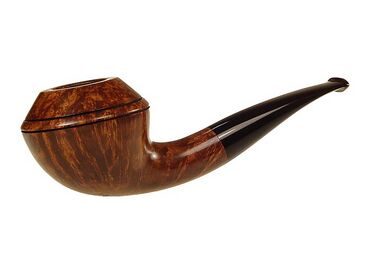

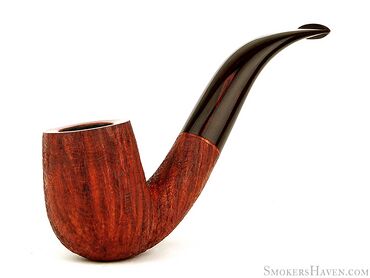

File: | File:Smooth Rhodesian.JPG|Jerry Crawford, Smooth Rhodesian | ||

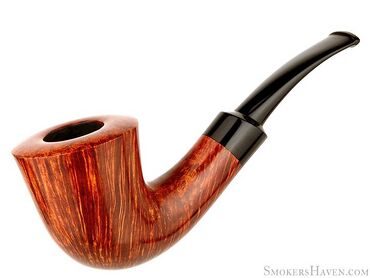

File:JerryCrawford-Dublin.jpg | File:JerryCrawford-Dublin.jpg | ||

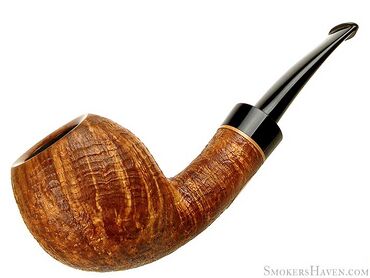

File:JerryCrawford-Danish Apple.jpg | File:JerryCrawford-Danish Apple.jpg | ||

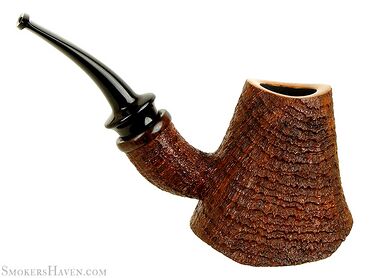

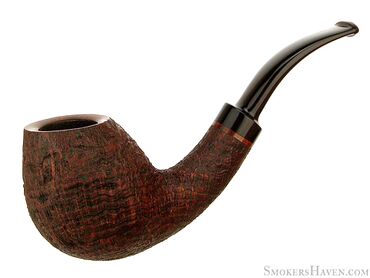

File:JerryCraford-BlastedVolcano.JPG|Jerry Crawford, Blasted Volcano, courtesy [https://www.smokershaven.com/new-pipes/jerry-crawford/ Smokershaven.com] | |||

File:JerryCrawford-RhodesianPartialBlast.jpg | |||

File:JerryCrawford-BlastedBentEgg.JPG | File:JerryCrawford-BlastedBentEgg.JPG | ||

File:JerryCrawford-Blasted-Author.JPG | File:JerryCrawford-Blasted-Author.JPG | ||

File:JerryCrawford-Bent Billiard 2.JPG | File:JerryCrawford-Bent Billiard 2.JPG | ||

File:JerryCrawford- | File:JerryCrawford 1 1 x700.jpg|Smooth Prince with Ox Horn, courtesy, [https://pipes2smoke.com/collections/jerry-crawford pipes2smoke.com] | ||

</gallery> | </gallery> | ||

== Contact Information == | |||

Website: http://www.crawfordpipes.com/ | |||

E-mail: crawfordpipes@gmail | E-mail: mailto:crawfordpipes@gmail.com | ||

Location: Grants Pass, Oregon | Location: Grants Pass, Oregon | ||

Phone 541-787-5356 | Phone: 541-787-5356 | ||

[[Category: Pipe makers by nationality]][[Category: United States]] | [[Category: Pipe makers by nationality]] | ||

[[Category: United States]] | |||

Latest revision as of 19:35, 6 December 2022

From the bio Jerry Crawford provided us:

Pipe maker Bio 2018

My love of pipes began many years ago as a child, my father had smoked a pipe and from watching him and old movies I always felt there was something interesting and special about pipes. Growing up I always enjoyed working with my father in his shop making cabinets, or furniture. My parents were both very resourceful and encouraged me to make or fix things and take classes on ceramics, metal working, wood working, leather crafts, plastics etc. during summer vacations. With a background in electronics and real estate which relied heavily on my attention to detail and creativity to be successful, the process of making pipes felt natural and gratifying to me from the start.

In the 1970s I began regularly smoking and collecting pipes. I always maintained and many times refurbished the estate pipes I bought, but sent them out for more extensive repair. In 2009 after getting a rare Comoy’s Blue Riband back from repair and saw the nomenclature had been completely removed, I committed to learning how to repair my own pipes. Around that same time I befriended Paul Hildebrand, owner of Pipe Makers Emporium. Upon learning he not only repaired pipes but had also been making pipes for the past 10 years, I expressed my frustrations with repairs and my desire to learn to do them myself.

After discussing some techniques used for repair, Paul invited me to spend a couple days working with him in his workshop, offering to show me the process of making pipes start to finish. In 2010 I made my first pipe and was immediately hooked. At that point the idea of just making repairs became secondary to making more pipes.

After winning a billiard contest with only the 3 rd pipe I had ever made, I met Rainer Barbi who was one of the judges. With his encouragement and some valuable tips that I use to this day, I began buying more supplies and began tooling up to make more pipes.

By 2012 I decided to work toward making pipes full time. In 2013 one of my pipes placed in the Greater Kansas City Pipe Clubs Carvers Contest. At that Kansas City show I met Premal Chheda and spent a week with him in his shop which helped me really fine tune my processes to better achieve the results I envisioned. In 2014, I was selected to make the pipe of the year for the Vancouver pipe club.

After many years living in and around Phoenix Arizona my wife Viki and I relocated in March 2016 to Southern Oregon, finally realizing a dream to have a place with a shop in the woods. Some 40 miles south of me is home to a good friend and pipe maker Brad Pohlmann who has graciously shared his time and workshop on a regular basis for the past 2 years. Working with Brad and Silver has not only been inspiring but has helped me achieve my goals as a pipe maker to create pipes as I envision them, sometimes even better.

All of the pipes I craft are made using the best Italian briar available from the most vetted cutters. Each stem is hand cut with integral tenons, from the highest quality German Ebonite rod stock with the exception of an occasional Bakelite or Lucite material. Special attention is always given to creating an open and unrestricted draw and features my signature funneled opening at the button.

Each pipe is hand crafted individually using time honored pre drilling or freehand techniques using the highest of tolerances to promote the superior smoking characteristics that have become synonymous with Crawford Pipes.

Gallery

- More examples from Crawford Pipes, courtesy Smoker's Haven

Jerry Crawford, Blasted Volcano, courtesy Smokershaven.com

Smooth Prince with Ox Horn, courtesy, pipes2smoke.com

Contact Information

Website: http://www.crawfordpipes.com/ E-mail: mailto:crawfordpipes@gmail.com Location: Grants Pass, Oregon Phone: 541-787-5356