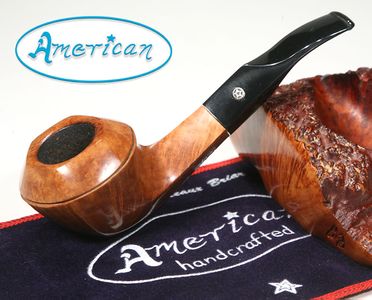

American Smoking Pipe Co.

In an article, called Go West, which originally appeared in the French Pipe Mag, Erwin Van Hove has this to say about Mark Tinsky: "His more than reasonable prices, and his good-natured personality, have made Mark [Tinsky] the favorite of many Americans. It is difficult to find an amateur who does not possess at least one pipe made by the American Smoking Pipe Company, that Tinsky founded in 1978 with his friend Curt Rollar. In 1990, after the departure of his associate, Tinsky continued on by himself building a solid reputation using quality briar from Greece and stem blanks imported from Italy, offering collectors a vast assortment of models and finishes. In short, his pipes are beautiful and well-made pieces that produce a taste beyond reproach. Neither off-the-shelf nor haute couture, they are solid hand mades for an affordable price. And by the way, it is Mark’s pleasure to carve the pipe of your dreams as he readily accepts commissions. Also noteworthy is a future changing of the guard of sorts, as his son Glenn has inherited his father’s talent, and, at the age of 16, is selling his own creations."

Mark Tinsky / Pipe Maker (in his own words)

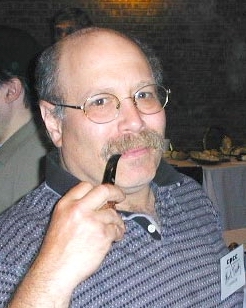

About the most frequently question asked of me, is, "how did you get into pipe making?" I usually plant my feet, make sure my bowl is lit, and say, "It's a long story, are you sure you want to hear it?" If the response is favorable I proceed.

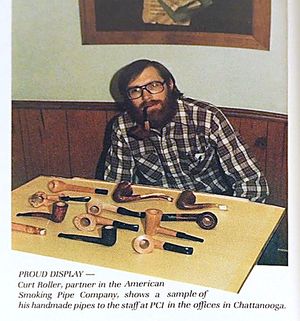

Sometime late in high school a buddy of mine got a job cleaning briar for a neighbor pipe hobbyist named Jack Weinberger. He wasn't a good worker and was pretty soon fired. Another buddy and my future partner, Curt Rollar, immediately applied for the job and got it. At first all he did was clean the tops and sides of the briar so Jack could more easily read the grain of the wood. As Curt was a good worker he stayed on while he went to college and soon became a pipe maker himself as Jack turned his hobby into a business. All my friends envied Curt's cool job as we worked at various menial teenage jobs at the time. As we had a good source of pipes (the 2cds) we started smoking pipes. Curt eventually liked making pipes so much he took it up full time.

Curt and I were avid bicyclists. We spent many summers touring the Eastern USA. Our dream, however, was to ride our bikes to Alaska. We lived in NJ. at the time. We accomplished this in 1974. I went back to school at Montclair State College, and Curt went back to work for Jack. Each summer after that we planned a major excursion. One year we rode to Nova Scotia. The following summer Curt hiked most of the Appalachian Trail before succumbing to a Giardia infection. I rode to the Gaspe Peninsula. These were only side trips, however as our new dream was to ride around the world.

When I finished school, I joined Curt in the pipe shop. We lived in a ramshackle apartment and rode our bikes to work in Jack's basement. We worked with Vic Steinhart, Jack's nephew, who later founded Briar Originals. I also worked with Scott Parfumi, who was the grandson of the famous Joe Cortegani, and Frank Augsburger, who served his apprenticeship at Jack's. We worked and saved our money for the big trip. In the meantime I certainly enjoyed making pipes. I started at the bottom and was able to work up to being a pipe maker before we left.

We had a great time on our trip. We went through England, Wales, Ireland, and Scotland. We ferried to Norway and crossed the Scandinavian countries before entering the European mainland through Denmark, into Germany. We crossed through Germany, Belgium and into France. We traversed the Alps in four days through Switzerland and into Northern Italy. We meandered down the Adriatic coast of what was Yugoslavia, through Sarejevo, and South along the Albanian border into Greece. Greece was a wonderful country with lots of good food and friendly people. The end of our oddessy came in Turkey. Sometime during the ferry ride from Greece someone stole our pumps and spare tires. We plugged along as best we could. Around that time the Iranian revolution began and we were advised that Iran wasn't a healthy place for Americans to be at the time. Tired and discouraged we called it quits in Ankara. We caught a bus back to Istanbul and flew home. Well, what's this got to do with pipe making?

One morning, while still in Yugoslavia, we decided we would make full time careers as pipe makers in our own business that we would establish when we got back. That morning, American Smoking Pipe Co. was born. We wanted a name that would distinguish ourselves from the overwhelming majority of pipe makers who were European. We were proud to be American pipe makers and we would make our mark when we returned. Our return was sooner than expected but we felt we had accomplished what we had wanted and it was time to move on to fresh challenges. One of our major misconceptions was that we would work only during the winter and leave the summers for bicycling. Needless to say that once we were in business for ourselves our bicycling days were over.

American Smoking Pipe Co.

The Early Days

We returned full of hope for our new business. Hope, unfortunately, doesn't alone get you started making pipes. By this time my parents had moved to Fla., so I lived in my tent in Curt's backyard. I don't know what the neighbors' thought but as it was a beautiful fall, I was content. By this time Vic Steinhardt had separated from Jack and was running his own company. We worked for him in exchange for briar. Briar can take up to 4 months to received and up to a year to dry so we needed dry wood in order to begin. A few months after returning Curt's grandmother died, (1978). She had been living on a 50 acre rundown farm in Frenchtown, NJ. The family wanted us to live there, as caretakers, until they could sell the place. Not ones to look a gift horse in the mouth I moved from my tent to a large rambling farmhouse. What a neat place this was. Curt's grandfather had been in the egg business for a time and had put up many barns and coops that were now falling down. One of our jobs was to demolish these barns. We sold off the old barn board siding, the large oak beams, and used some of the lumber to refurbish a more modern tool shed where after installing a Franklin stove, we established our first shop.

With what money we had left from our trip we purchased a bandsaw and drill press from Sears and commissioned a machinist to make sanding discs and shafts to mount polishing wheels on. We used the lumber from the barns and old motors we found around the property to make tables and sanding and polishing set ups. It was a cold winter though. The tool shed was uninsulated and the stove inefficient. The farm house wasn't a lot better either! I guess we suffered a bit for our art that year. Some time that Spring our first wood order came in. We were so excited. Using the wood we had gotten from Vic, we had our first pipes ready for sale in July of 1979. Our first thought was to call on customers we knew from Jack's. Not many were as accepting as we expected. By then JHW was a name in pipe making and an easily salable pipe. By this time the quality had slipped as Jack had gone back to hiring high school students and he himself was incapable of making them himself. We found out that a recognizable name is a very important in selling pipes.

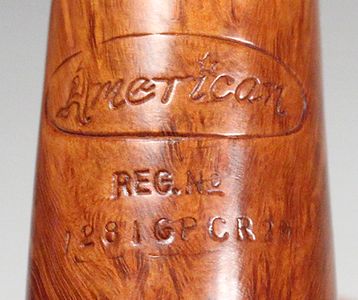

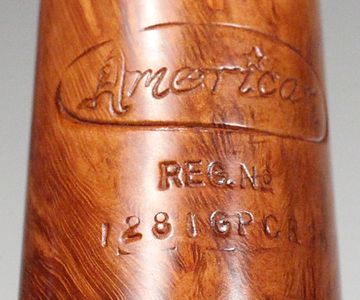

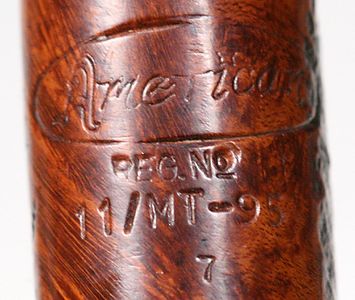

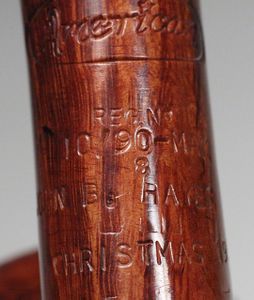

- Early examples and nomenclature, courtesy Doug Valitchka

A few stores that knew us did want to see what we had made. In an effort to separate ourselves from JHW style pipes we made more classical shapes than the wild freehands that were the JHW repertoire. We slowly built our inventory and did a lot of knocking on doors to gain recognition in the industry. I'd like to say our pipes immediately took off like wildfire and there was no looking back from there. What really happened was that we went through a very slow building process and we were able to take advantages of breaks when we got them.

One of our earliest breaks occurred in 1980. I had been to every major store in Washington DC. without making a sale. I went into Georgetown Pipe and Tobacco in the evening and gave my pitch. As I was politely being asked to leave by the manager, the owner, David Berkebile, happened upon us. He agreed to look at the pipes and even bought a dozen, our biggest sale yet and to one of the better shops in the country. I 've always felt indebted to David for looking at our pipes that night. It wasn't make or break but I was getting pretty discouraged. Our next big break was getting into the Tinder Box at the Lennox Sq. Mall in Atlanta, GA. Allen Mandell was the owner, I swear he could sell horse manure to a farmer. He was a great pipe salesman and a great B.S. artist. He would sell pipes to people who came into his shop for cigarettes! On Saturdays, customers would be lined up three deep along the tobacco bar for the privilege of buying very expensive pipes from Allen. They clamored for his attention while he was busy yelling at his wife or his manager, or anyone else who displeased him. The shop was amazing. Well when I came in he turned away from all this and started selling my pipes right from the wagon that I used to drag them around in. That Saturday we must of sold a dozen or more. He invited me back to his house to stay. Before I left he must have picked out another 5 dozen pipes. He later told me he had a little trouble selling the first bunch. Considering it only took a couple of months I thought he did pretty well. Turns out he had doubled our RETAIL prices instead of the WHOLESALE and sold them for double their asking price. I sometimes wonder if this wasn't unintentional. (Allen past away in January,1997. A good friend and tremendous pipe person!)

As word gets around quick in the industry about someone's success we were now having an easier time getting in to see stores. As our pipes smoked well we were getting increasingly larger reorders. Our biggest break came in December of 1981 when I met John Hayes. John had worked as general manager of Georgetown Tobacco, though I had never met him. He opened his own store the weekend I was in town to do a Christmas show at the Georgetown store. Apparently this was unbeknownst to David as his son in law George Brighton had arranged the show. He was quite perturbed with George, he remonstrated , "We have enough of our own stock of unsold pipes to sell. This isn't the time of year for a pipe show."

As George had been the one trying to get me out the door the first time at the shop I did enjoy his discomfiture a bit. Being quick on his feet he suggested doing a show at a shop that was just opening that weekend in the Fair Oaks Mall , Fairfax, VA. About 25 miles West of DC. He made arrangements and off I went to John B. Hayes Tobacconist.

They had a good crew of people putting the finishing touches on the store when I walked in. Everyone was young and enthusiastic about getting the store off the ground. I fit right in and helped as I could. The next day we had a lot of curious lookers . We did sell about 15 pipes on Saturday and another 9 on Sunday. Most were in the $25-45 range but at least it was a start. John and Cathy, his fiancée, and I became good friends. We had many common interests and since then they have become my best friends. Our pipe business took off with John's success. We sell hundreds of pipe a year in his store. At times he had more of our pipes on hand then we did. It was John's idea to start the annual Christmas shape . We 've made 13 of them. In the hey day of pipe sales we sold 150 Christmas pipes in John's store in 1987. These were all high end pipes that started at $75 for a sandblast.

The farm was sold in the end of 1979 and we needed to find a cheap place to live. We had always liked the Pocono's in Eastern Pa. It was also a real cheap place to live so we packed up the shop and moved to Saylorsburg, Pa. A bucolic village that the 20th century had seemed to leave behind. At least on weekends when we looked took the rental. We moved the entire shop in a van. In our next move it took 3 of the largest U Haul trucks. As I said Saylorsburg was real quiet on the weekends, but the following Monday we found out there was a quarry located down the road . When the bog trucks rolled by our little house shook. Our shop though was inside the house in a large basement. This was a real step up in the world for us. It had a two car garage for storage and only cost $240 per month. To supplement my income I opened a karate school at the local YMCA, where I still teach today. In Saylorsburg there were few distractions and we settled down to produce a large volume of pipe making. Our business flourished and by 1982 we had saved up enough money t buy our own house. Its main attraction was a large new shop in back of the house. We moved in October of 1982. This was also the year our mentor, Jack Weinberger died.

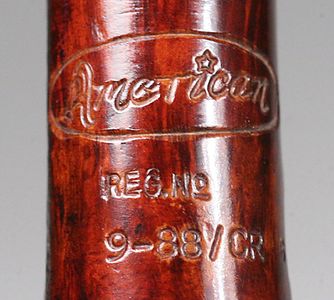

- Several American Smoking Pipe examples, details, and nomenclature courtesy Doug Valitchka

More Recent History

The story of pipe making in the 80's is a story in its self deserving of a fuller treatment than I can give here. I will address this subject more completely in later writings. There are many stories, many personalities, and a whole era to recapture. For me this was a happy time. I got married had a child. Had time to pursue personal interests after concentrating solely on the business for so many years. We were accepted by the Pipe World in general. We made various club pipes for PCI magazine. We were in many retail catalogs. I went to Europe to buy briar and stems directly. Things were going well and we enjoyed the recognition and fruits of our success.

Change is the one constant you can count in life .Curt had carved out a life for himself. He got married and bought his own house in 1986 and learned kayaking which he is expert at today. In 1990 when I wanted to expand our business, hire employees etc. He decided he wanted to do other things with his life. In my opinion he was the premier pipe maker in the country; he had been making pipes for 20 years at this point and was ready for something new. I was surprised to say the least, but as we had been friends since the 7 th grade this was more important than our business partnership. We amicably settled our business, I retaining sole proprietorship of American Smoking Pipe Co.

- Example and detail from 1991, courtesy Doug Valitchka

Soon thereafter, I divorced . It was a rough year. I set up shop in a friends storage shed. It was 12x20' and large enough for two people to work in. She came to work for me as a polisher and I was soon back in business again. I guess I too was looking for a change and I incorporated pipe repair into my work for the first time. Unfortunately, this alienated a couple friends of mine on the East coast who were pipe repairmen who didn't like this encroachment. One, Howard Shulte, still isn't speaking to me today, as John Hayes went with me instead of him. I enjoyed learning pipe repair. Its a lot different than pipe making. Some of its mundane, of course, but there are a lot of interesting problem solving opportunities that I find challenging. As it turns out this was a wise decision.

For whatever reasons the bottom of the new pipe market dropped out after 1992. We experienced a recession, anti-smoking laws stiffened, and the older pipe smoking generation was passing on and nothing was taking its place. Pipe smokers continued to smoke and need repair. They were able to smoke in fewer places and there collections became concentrated at home. They just didn't need as many pipes. Gray marketing, inflated prices by the big pipe companies also hurt new pipe sales. The interest in the used market was market was peaking as large estate collections were becoming available. Being able to smoke in fewer areas concentrated pipe smokers collections at home. Smokers didn't feel the need for new pipes as they no longer could be spread around their various habitats.

- Examples and detail from 1995, courtesy Doug Valitchka

- Examples and detail from 1999, courtesy Doug Valitchka

The Present

My current interests include fly fishing, reading, and writing about pipes over the Internet via Alternate Smokers Pipes newsgroup and Pipe Digest. I see a great future in this new form of communication and it has begun to change the way I'm doing business already. I can now deal directly with customers as I could never do before. I've met many interesting people who have used computer programs to design pipes. I plan to straddle the line between retailers and direct sales by protecting a retailers local territory. Its a big country and now with the Internet, a big world! I'm sure there's room enough for me to do business without upsetting too many people. I plan to do further writings about people, stories, and experiences I've had in the pipe industry. I've collected some of my writings on pipes in a section called Musings from the workbench. If you're interested, please look for further updates. Time for a new bowl of tobacco.

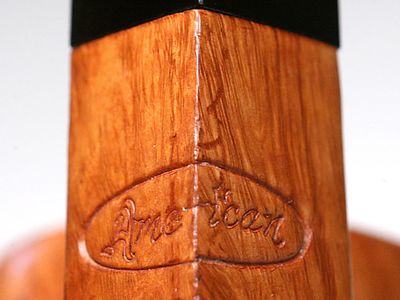

Stampings & Logos

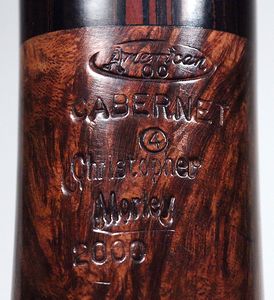

Early pipes had mainly the (American) logo and REGD. No and minimal stampings for date and initials of the carver. CR was for Curt Rollar, MT for Mark Tinsky. The stamp 07/99-MT would mean July 1999 by Mark Tinsky. If there's a number afterward I think it might be the number of pipe in that month. During the mid-1980's the MT stamp was lost, and in place of that the stamp *Z was used instead, so those *Z stamps were made by Mark Tinsky. There were also markings for specific editions of pipes, like Christmas, or the Christopher Morley, Cabernet, etc.

Logos - The first logos appear to be a simple star outline in white on the surface of the stems. Next would be a brass circle with a star inside, uncovered. Next is a black logo with white star inset under a clear acrylic. And later a briar ring was added to surround that in the stem side.

- Christoper Morley Cabernet series pipe from 2000, courtesy Doug Valitchka

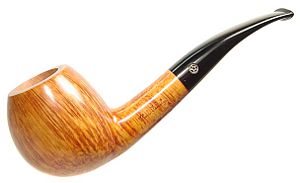

- Capital District Pipe Club's 2009 Pipe of the Year (Sunrise Finish), Courtesy Chip Fadeley

Chip states "I asked for two stems: one regular and one a little larger 41/2". Instead, I received a cumberland straight tenon military type curved bit wherein the removable shank extension with the star emblem stays in place and the stem itself removes and the churchwarden stem is then inserted. I purchased the dark blue lucite stem, from Mark Tinsky, afterwards. It looks deep black."

Addendum

With the renaissance in pipe smoking I've gone back to being a full time pipe maker. Certainly, my first love! My biggest problem is trying to wade through my list of custom order pipes. I can never seem to get caught up. Just once in a while I'd like to work on a few of my own designs! I'm not complaining business is great and I'm making pipes again. We'll have to see what the rest of the decade brings but its wonderful to have reached the point where everything I make can be appreciated and quickly sold. While I certainly haven't reached the lofty status of some of the European makers as Curt and I had dreamed of doing 20 years ago; at least nationally I do have some name recognition for which I'm grateful! Maybe the next generation of American pipe makers will put us over the top.

- You may also enjoy listening to Brian Levine's interview with Mark on the The Pipes Magazine Radio Show

Contact Information

American Smoking Pipe Co. POB 13 300 High St. (only necc. for UPS/Fedex) Wolf Creek MT 59648 E-mail: mailto:mt@MT.net Website: http://www.amsmoke.com/