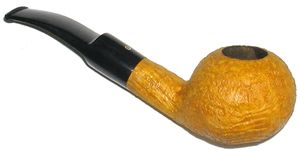

Ashton

L'histoire des pipes Ashton

A man makes his mark

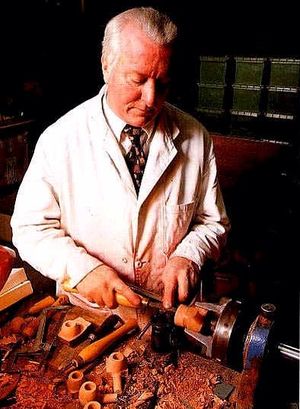

Un homme crée sa propre marque "William Ashton-Taylor", fabricant des pipes ASHTON.

Toutefois, à 15 ans, on ne commençait pas tout de suite par dessiner des pipes pour Dunhill. Il y eut un long apprentissage, durant lequel il fallait souvent balayer les débris de bruyère et d'ébonite, et servir le thé aux pipiers. Mais Bill montra un vif intérêt pour l'apprentissage du métier. Avant même qu'on ne lui permette d'essayer de fabriquer des pipes à l'atelier, il rapportait à la maison des têtes de rebut et des tuyaux pour faire des essais.

Plusieurs des meilleurs pipiers de l'atelier avaient remarqué l'intérêt de Bill, mais c'étaient des artisans très sérieux, et chacun d'entre eux avait mis au point ses propres procédés au fil des années, aussi se refusaient-ils à les partager avec d'autres, laissant le nouveau venu sur la touche. Finalement Harry Saigrott, qui avait perçu l'exceptionnel talent naturel de Bill, commença à partager avec lui son expertise dans l'art de faire les tuyaux et de les ajuster à la tige. A la longue les autres vinrent également et Bill put apprendre tous ces procédés gardés jalousement qui avaient fait des pipes Dunhill les meilleures du monde.

Le parcours d'une marque

Au début des années 80, Bill ressentit intensément le besoin de créer sa propre entreprise pour retrouver les très hauts standards d'autrefois, à la fois dans les modes de fabrication et les produits finis. De l'instant où fut fabriquée la première pipe qui porta son nom jusqu'à aujourd'hui, les pipes ASHTON ont été fabriquées avec les meilleurs matériaux et la plus grande maîtrise. Et parce que personne aujourd'hui n'en connait davantage sur la façon de faire les pipes les meilleures que William Ashton-Taylor, il n'y a pas de garantie plus probante de la haute qualité des pipes ASHTON que l'homme lui même.

R.D.Field joua un rôle essentiel dans la transformation du Bill Taylor de chez Dunhill en celui qui allait devenir le père des pipes Ashton, Bill Ashton-Taylor. Field a écrit la chronique de ce passage dans The Ashton Pipe Story

Du fait de son savoir irremplaçable dans la fabrication des pipes et le traitement de la bruyère, il obtint un brevet anglais pour sa technique de fabrication. Ce traitement spécial aboutit à des pipes plus légères de 12-14% que les pipes comparables d'autres marques. A propos de ces pipes faites main, Bill déclare: "Pour nous, toutes les parties de la pipe sont d'égale importance, qu'il s'agisse de la tête ou du tuyau. Dans les deux cas le meilleur matériau et une finition parfaite sont essentiels". Chaque pipe Ashton, par conséquent, démontre sa qualité du fourneau à la lentille.

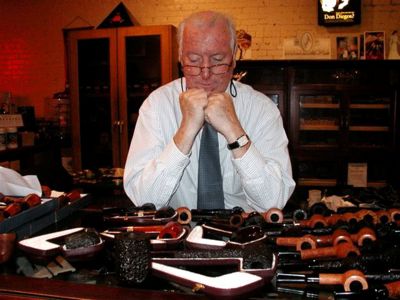

Wood makes the pipe

The purchase of selected briar wood is the most important pre-condition for the manufacture of high-quality pipes. Thus Bill insisted upon selecting the wood for ASHTON pipes himself. This is a privilege very few pipe makers enjoy today. Bill traveled to Italy twice yearly in order to select and purchase wood. And he has developed such a special relationship with the briar saw mills in that country that only he can command the truly huge pieces of briar that are required for the ASHTON "magnum" pipes so prized by collectors worldwide.

Bill used Calabrian briar for his smooth finished pipes because the wood is both hard and light, coming as it does from a light, sandy soil. Often he took these straight grain plateau blocks and turned them on their sides in order to fashion beautiful cross grain/birds eye pipes which are widely believed to smoke cooler than straight grains.

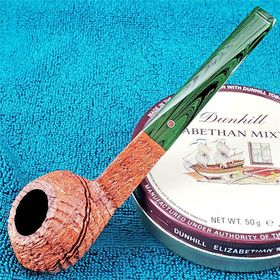

Briar from Tuscany is used for the ASHTON sandblast finishes, as this type of briar takes on a rich, deep patina after the soft grain is removed by the sand-jet. Ashton sandblasted pipes are often compared to early Dunhill Shell pipes, which are highly prized for their deep, craggy sandblasting. While Dunhill seems to have, by and large, abandoned the deep sandblasting technique as time has progressed, Ashton revived the practice, as can be seen on Ashton sandblasted pipes.

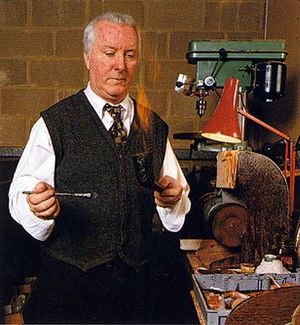

The method makes the difference

The manufacture of ASHTON pipes is based upon an ingenious method first developed in 1915 and improved upon after years of experimentation by William Ashton-Taylor. After the pipe bowls are turned from briar blocks they are heated for eight hours in order that they expand. They are then steeped for an additional eight hours in a mixture composed of three beneficial oils. During this procedure the wood acts like a sponge in soaking up the oils.

After steeping, the oiled bowls are placed on heated brass pegs where they reside for fourteen days. Throughout this period the oil "exudes" from the briar, bringing with it unwanted sap and residue and leaving behind the nut-like flavor for which ASHTON pipes have become renowned.

The torch is passed

William Ashton-Taylor passed away on September 16, 2009. Jimmy Craig is the only person we are aware of that carries on William's traditions in crafting pipes the “Ashton” way and this can only be verified by you, the pipe community as you experience his work. It is hoped that Jimmy will continue William's legacy, as the art of crafting smoking pipes is now a very rare skill indeed. Ashton-Taylor Pipes hopes that you agree that the quality of Jimmy’s work is indeed that of William, for William was very proud of the work that Jimmy was producing for him in 2008 and 2009.

You might also enjoy listening to Brian Levine's interview with Jim Craig on the Pipes Magazine Radio Show

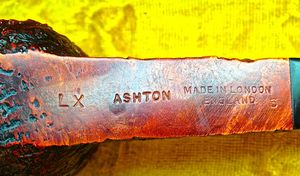

Dating

The first pipe was made in 1983. From this year and at least up to 2002 pipes were stamped with a suffix number after the origin "Made in England". It starts with no. 3 in 1983 and continues counting up to no. 25 in 2005. First year pipes were stamped with simple block lettering and did not include a finish stamping. The origin on first year pipes was stamped "MADE IN LONDON ENGLAND". There were only 31 pipes made in total in 1983, which means they are quite rare and sought by Ashton collectors.

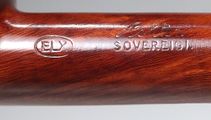

- Circa 1998 EXL Sovereign, courtesy Doug Valitchka

Finishes & Grading

Ashton Pipe Finishes & Grading:

- 1: Sandblast -

- a. Pebble Grain (Pebble Grain) - dark

- b. Old Church - Natural (OC)

- 2: Claret & Gilt Edge - smooth with a burgundy to gold burgundy color

- 3: Oak - dark smooth

- 4: Sovereign - smooth natural

- 5: Sovereign SG - smooth natural straight grain, # 1- 5

- 6: Achievement - pipes that have some unusual work on them, spiraling, bamboo etc.

- SIZING: X, XX, XXX, LX, ELX, Magnum

- Various examples and details, courtesy Doug Valtichka

- Ashton Old Church 215 XXX by Jimmy Craig, courtesy Dennis Dreyer Collection

Photos by Chance Whittamore

Off site links

Robert C. Hamlin has written an excellent piece on the Ashton pipe story available on his PipeGuy website

Contact information

Email: mailto:ashtonpipes@googlemail.com

Ashton pipes are available from

Pipes2smoke.com: pipes2smoke.com

McCranie's Pipe & Tobacco Shop - North Carolina, USA website

J.J. Fox - 19 St. James Street, London SW1A 1ES website

Smith & Sons - 74 Charing Cross Road, London WC2H OBG

Shervingtons - 337/338 High Holborn London WC1V 7PX

Greens of Leeds - 37 the Headrow, Leeds W. Yorks LS1 6PU website

Lands Tobacconist - 29 Central Chambers, Henley Street, Stratford Upon Avon Warcs. CV37 6QN

James Barber - 33 Kirkgate, Otley W. Yorks LS21 3HN

Bisgaard Pipes - Adelgade 3 DK-8400 Ebeltoft, Denmark website

Clive Humm - 243 Berkhampstead Road. Chesham Bucks HP5 3EQ England [straightgrain.connect-2.co.uk/ website]

Kohlhase, Kopp & Co. - Hermann-Lons-Weg 36, D-25462, Rellingen, Germany. mailto:Kohlhasek@csi.com

"Piepenhoeker" Rolf Osterndorff, Suedersteinstrasse 16, D - 27472,Cuxhaven, Germany. website E-mail: mailto:info@piepenhoeker.de

Heroes & Legacies - 10,000 Research Boulevard Suite 214, Austin, Texas 78759 Tel: 512-343-6600 Fax: 512-343-0933 Contact: Pablo Caballero E-mail mailto:heroesandlegacies@heroesandlegacies.com

Lubinski S.R.L. Via Respighi, 24 63023 Fermo, Italy. E-mail mailto:cigatoba@tin.it

McGahey the Tobacconist, Exeter,Devon. website - E-mail: mailto:mcm@the-tobacconist.co.uk

Pijpenkabinet Amsterdam (National Pipe Museum with the national pipe collection Smokiana, the pipeshop for modern and antique pipes) have been appointed exclusive distributors for Ashton Pipes in Amsterdam. Address: Prinsengracht 488, 1017 KH Amsterdam, Netherlands. Tel: 00-31-2042 11779 - website

Broadweighs Cigars - 48 Broad Street, Teddington, Middlesex. Tel/Fax 0208 977 3793. website