The Early Dunhill OD

THE EARLY DUNHILL OD, © JOHN C LORING: Used by permission

Contributed by Jean-Christophe Bienfait

Introduction

Traditionally the “OD” has been the most collectable of Dunhill pipes, yet historically speaking we know little about it. It’s origins are uncertain. I suspect it dates to the early 1920’s, priced in line with the straight grained DR and above the letter designated shapes which in turn were initially priced somewhat higher then the ‘standard’ number designated shapes (subsequently, in the 1920’s, the letter and number designated shapes were priced the same). The meaning of “OD”, which is sometimes found with a following letter ranging from “A” to “J”, a further price/grade indicator based on overall production costs and quality of the pipe, is not definitely known but it is consistently said to stand for “Own Design”.

If we are not quite sure when the line began or what it was intended to be our knowledge doesn’t get much better when we try to define what it actually was before 1953. Generally our knowledge of Dunhill pipes comes from reviewing both catalogues and surviving pipes. But unfortunately, when it comes to ODs prior to 1953 we find only isolated catalogue references and few surviving examples. Still there are some references, some examples and some other source material and in this paper I will try to patch these together, all the while recognizing that like all such efforts in time there will be revisions.

In this paper I will suggest four relatively new, perhaps controversial, thoughts leading to the conclusion that the ‘Modern ODA Line’ began in 1953. First, that due to economic circumstances there was never an OD retail pipe line as such prior to World War II. Second, that the post war ‘ODA’ pipe line that we all know wasn’t Dunhill’s initial post war objective, but rather came about in the fluidity of a changing customer base and competition. Third, that in the post WWII period smooth finished oversized standard shape pipes, ‘semi-giants’, were uniformly stamped ODB rather then ODA only because of the then high cost of Italian briar. And fourth, that in 1951 and 1952 ‘semi-giant’ Shell finished pipes were not considered part of the post-war OD line. Lastly, the reader may perceive a veiled suggestion that Dunhill might be viewed as the pre WWII parent of the high grade ‘Free Hand’ briar pipe – that should raise some hackles.

PRE WORLD WAR II

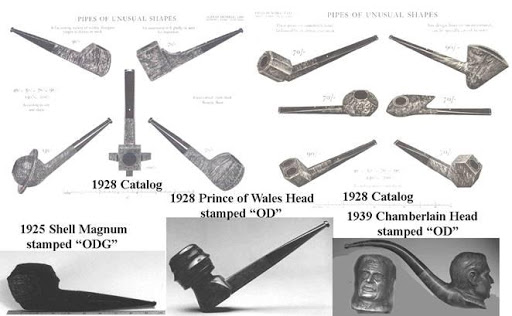

From inception Dunhill was an innovative pipe maker, not only in terms of mechanics but also in terms of design. The non standard letter shapes of the 1910s, the “LB” billiard, the “R” pot, the “P” bent bulldog and the “K” apple quickly became important standard shapes of the 1920s and after. And the quaint shapes of the 1920s likewise found a welcoming audience:

That said the pre-war OD is nonetheless almost mythical. In terms of catalogue references and reported surviving examples we know of less then two dozen pipes, most of which are pictured here.

Further confusing the picture, as shown below we know of three ‘group 6sh’ pipes dating from 1928 to 1931 stamped “DR” but which seemingly could just as easily have been stamped “OD” with a place in the 1928 OD catalog pages:

There is also a small pre World War II ‘sketch book’ in the Dunhill archives illustrating perhaps fifty ODs but as I have not been able to study it in detail I can not be certain if any of the sketched pipes were actually carved, a particularly important question mark since execution of some of the sketched pipes would appear to have required use of spliced briar elements and non-briar materials.

I can however, make a few observations.

First, while at least in 1928 the OD was priced and graded roughly in line with the DR, far, far fewer pre-war ODs were produced as compared to pre-war DRs or any of the rare shapes such as LCs and magnums. That is to say that the OD is easily the rarest of Dunhill pre-war pipes.

Second, with one exception all known pre-war ODs are smooth finished pipes and taking into account what we know about the early post war OD, it is most likely that in the pre-war period the OD was understood to be a smooth finished pipe.

Third, unlike the general pre-war Dunhill ‘quaint’ shapes which were without exception ‘group 3’ and ‘group 4’ in size, the pre-war OD was a large pipe. The smallest, the carved heads, were ‘group 5’/’group 6’ in size, the ODs shown in the 1928 catalog were as a whole large ‘group 6’, and the ODG BullDog pictured above appears to be the largest known pre-war Dunhill pipe. Yet size alone did not make an OD, to wit: dozens of pre-war Dunhill magnums are known, but the pictured ODG is the only one with an OD stamping; likewise the LC bent shapes and the 482 billiard shape are ‘group 6’ sized pipes, yet none were stamped “OD”.

Fourth, if size alone didn’t make an “OD” the same seems to hold true for specially carved pipes as well. For instance in addition to the three DRs pictured above I have a 1937 Dunhill “Bacchus” head, in all respects at least the equal of the above pictured “Chamberlain” OD, but which is not stamped “OD”.

Fifth, the OD is completely absent from Dunhill catalogs until 1928, and then save for one repeat page in an early 1930’s catalog, disappears again.

All of this leads me to the following speculation: The Dunhill 1928 “About Smoke” catalog, easily Dunhill’s finest, was in fact a prideful statement of the Company’s astounding growth over the then past decade, and a roadmap for its then intended future. Part of that roadmap was the introduction of the “OD” line, a line of unique, large ‘one of a kind’ ‘hand pipes’, reminiscent of, but quite different from, the elegant meerschaums of the previous century, and essentially new to the world of briar pipes (Danish, Italian and the other English ‘free hands’ are post WWII phenomena). I suggest that a full two page exhibit of these magnificently carved pipes where before there was nary a whisper hardly leaves room for any other conclusion. But unfortunately it was a still born introduction given the dramatic world wide economic collapse that shortly followed.

By this I do not mean to suggest that the OD began and ended in 1928, for obviously the 1925 magnum and the 1939 carved head pictured above demonstrate that it did not. But I do mean to suggest that for most of the pre WWII period the OD existed more as a concept then as a retail line of pipes. Custom ordered high end pipes at above standard pricing might be referred to as ODs but there was no need to stamp them such since the pipe and invoice went directly out to the ordering customer. Likewise if an occasional specially carved premium priced pipe was put out for sale in one of Dunhill’s London shops, the experienced staff of those two shops could be trusted to recognize such a pipe and recall or check for the correct price without the need of a special OD stamp. Essentially then this meant that the OD stamp was needed for only those few pipes put out in the retail stream beyond London.

POST WORLD WAR II

Commencing in 1950 Dunhill introduced a line of pipes assigned three digit shape numbers starting with 8, the “800” series, and stamped with an “OD” followed by a letter grade stamp above that shape number. In contrast to the pre-war ODs these post-war pipes were often considerably smaller and, regardless of size, were ‘production line’ pipes as opposed to the ‘one of a kind’ pre-war ODs. These “800” series pipes essentially fell into two sub-lines: ‘fancies’ (my term): shape numbers beginning with 80_ and 86_; and ‘semi-giants’ (the Dunhill factory term): shape numbers beginning with 83_ (and later 84_ and 85_). The fancies (80_and 86_ ) were as a whole ‘group 4sh’ sized pipes reminiscent of some of the pre-war quaint shapes with the 80_ shapes recalling earlier times and the 86_ shapes looking towards the future. The semi-giants (83_ and also the 806) were larger,

‘group 5sh/6sh’, versions of standard shapes. In fairly short order the fancies fell by the wayside and the semi-giants developed into the pipes we commonly refer to today as “ODA”s. But to begin to understand and speculate how and why this happened we have to step back a few years.

For Dunhill, like all English companies, the period from 1939 through 1953 was particularly difficult. During the World War II itself Dunhill production suffered from severe shortages of briar, vulcanite, and tooling and least we forget, an over abundance of aerial bombings. And for several years after, while the details changes, the difficulties did not. Until the 1950s Dunhill pipe production appears to have been lower then when it was a fledgling company in World War I and after thirty consecutive years of annual pipe catalogs there wasn’t even one such for the entirety of the 1940s.

Following war’s end the supply of vulcanite and tooling freed up, but briar was not so readily available. Italian briar which Dunhill used for its smooth finished pipes didn’t become available in blocks suitable for larger pipes until 1948 and then initially only at very high prices. The supply of Algerian briar became available sooner but Dunhill used that briar only for its Shell finish pipes. Equally, if not more importantly, there was a dramatic change in Dunhill’s customer base, in short for all practical purposes only Americans could afford to buy Dunhill pipes in any volume. Thus targeting the American market was of utmost importance. And in that latter regard there was a particularly irksome development amongst the competition.

Barling began making pipes long before Dunhill but unlike Dunhill before the war Barling had concentrated almost exclusively in making ‘group 3sh/group 4sh’ air dried smooth finished Algerian briar pipes for English pipe shops to be sold in England. Remarkably however, with hardly any prior export or large pipe experience after the war Barling began to successfully target the American market and significantly expanded it’s line to include much larger standard shape pipes (the “EXL” & “EXEXL” sizes) that many American pipe smokers soon came to prefer. In one respect however, Barling was handicapped. Because Barling used soft air dried untreated Algerian briar it could not effectively produce a counterpart to the popular Dunhill oil and heat treated Shell finish as all too often sandblasting would simply blow away the soft untreated Algerian briar (later Barling compensated by producing sandblast pipes from harder, non-Algerian, briar). However, this was not an immediate problem as initially Dunhill was not producing meaningful numbers of large pipes in any finish.

Dunhill of course was not without experience in making large pipes, the LB, the LC, the 482, the ODs and of course the magnum, but aside from the LB none of these pipes had been of particular commercial success. So in terms of Dunhill’s pre-war world wide market, of which the US was only a part, the large ‘group 6sh’ pipe was of little import. On the other hand, as discussed earlier, in that same pre-war period Dunhill had had success with medium sized quaint pipes.

I still recall when I first saw the fabled first post war catalog pages from the Xmas 1952 & 1953 catalogs each picturing a few ODs. With minimal knowledge of Dunhill’s history and knowing only that “ODA” meant a large Shell classic shape pipe, I was much let down by what I saw – comparatively small, only smooth finishes and generally weird:

But now it is easy to see that in circa 1950 the essential perception at Dunhill, especially given the constraints imposed by a limited supply of Italian briar, was a line of development from pre-war quaints to the 1928 style ODs to the post war fancy (80_ and 86_) ODs, and not to the semi-giant (83_) ODs that were the focus of my untutored, late 20th century, perceptions.

But if it was a logical progression Dunhill was quick to see that logic aside, these OD fancies were not what the American pipe smokers were looking for. And Dunhill was equally quick to see that the for the most part the semi-giant ODs were favorably received, as were Barling’s EXLs and EXEXLs, and as were Dunhill’s larger Shell finished pipes for which Barling had no meaningful counterpart.

The earliest of the semi-giant 83_ shapes that we presently know of are a pair of 1949 Shell 832s (saddle bend “LB”sh lovat) stamped only “ODA” without a shape number since the 800 series shape numbers were not implemented until a year later. These were followed by the 806 (apple), 830 (liverpool), 831 (small bent), 834 (prince) 835 (tapered bit billiard), 836 (square panel), 837 (bulldog), 838 (straight rhodesian), and 839 (bent rhodesian). A late 1952 factory memo bearing a later, 1980’s, Dunhill archivist annotation suggests that through 1952 effectively all of the new ‘800 series’ semi-giant ODs were smooth finished and because of the then high cost of the briar, were graded ODB. (Note the situation differed with respect to the smaller smooth finished fancy (80_ and 86_) shapes where grades ODA, ODB and ODC are all found.)

In both respects (all smooth finishes, all ODBs) I find these suggestions supported based on what I have seen.

First, as discussed earlier up to this point in time the OD line was essentially viewed as a smooth finish line.

Second, I know of no smooth finished semi-giant (83_) OD pipes stamped other then ODB prior to 1953.

Third, aside from the two 1949 832 Shells noted above the only semi-giant type Shell pipes from this period that I know of are a 1952 835 stamped as a group 4, “(4) 835”, rather then “OD” and a 1950 “LOX” (for all intents and purposes an 837) also stamped (in 1951) as a group 4 rather then “OD”.

This strongly suggests that in 1950/1951 when the group size system was considered and implemented it was determined that the larger, semi-giant type Shell shapes, which would be considered “ODB”s if smooth finished, should not part of the OD line and instead priced as Group 4s. This I should add is consistent with the pre-war practice of treating large Shells such as the LC or the 482 as standard price shapes.

In short then I am presently of the view that up to 1953 the post-war semi-giant OD line essentially consisted of smooth finished pipes uniformly graded ODB because of the high cost of Italian briar and that while a few similarly shaped Shells were graded ODA through 1950, in 1951 and 1952 such Shells were not considered part of the semi-giant OD line and instead graded as Group 4s.

Beginning in 1953 the smooth finished semi-giant ODBs were downgraded to ODAs, I assume due to a combination of reduced briar costs and competition (I know of no ODB or higher stamped semi-giant pipe after 1952 until the recent reintroduction of the OD semi-giants). At the same time Shell finished Group 4 semi-giants were upgraded to ODA, began to be produced in large number and soon came to be the dominate the new ‘ODA line’. Thereafter the balance of ODA semi-giant shapes (84_ and 85_) were filled out, Barling’s temporary large pipe dominance of the American market was thwarted and the OD 800 series fancies (80_ and 86_) were abandoned.

Thus was born in 1953 the modern Dunhill “ODA” line.

While I am not sure that Richard Esserman would agree with all the thoughts expressed in this paper, in important respects this paper is the result of an ongoing dialogue between the two of us over the years.

Back to Loring's articles here