Dunhill Additional Stamps

I’m not sure whether it was Barry Levin or Bob Hamlin who first recounted the story of a visit to a famous pipe maker who explained that some nomenclature changes were simply the result of mislaying the right stamping tool and then later finding it again, but the point is not all pipe nomenclature is consistent or lends itself to ‘logical’ explanation. Similarly, Michael Friedberg in his ’89 article on early Dunhill dating advised that "In the early years, Dunhill was not always consistent in its stampings." quoting for support Dunhill archivist Gomersall’s letter to the effect that:Alfred Dunhill was very much a perfectionist, and while inconsistency and inadvertent omission are a necessary part of the human condition, I interpret Mr. Gomersall’s comments differently, for I have found that with respect to Dunhill nomenclature, seeming inconsistencies when viewed with sufficient nomenclature examples or given thought do in fact reveal a fairly consistent logic. So rather, I interpret Mr. Gomersall as simply saying that early Dunhill nomenclature is not without its complexities, that the factory records are incomplete for this time period, and the time increasingly distant. Thus when faced with seeming inconsistencies (e.g. the circled and uncircled "A") I believe it is most probably the result of having not yet developed a sufficient universe of pipe nomenclature examples to allow for an understanding of the underlying logic or alternatively simply not having thought the complexities through."We hope you can appreciate that it is only with some trepidation we issue information on this subject especially in reference form, for from our experience, the interpretation of such data, can be and often is, much adrift. The markings have to be taken as points of evidence and weighed in the balance of experience and ‘feel’, for at times all the factors do not add up for the uninitiated to make a positive judgment."

Loring, J. C., THE PRE ’25 DUNHILL PIPE - INCONSISTENT NOMENCLATURE (self-published, Chicago, 1997).

The reason for dating a pipe was due to a one-year-guarantee offered by Dunhill, that they would replace a pipe if it had any issues in its first year. Sometimes, a pipe would be made and stamped, yet wouldn’t leave the factory until the next year or even later, when it would then receive a current extra date-code. Due to this, there are several examples of pipes with double, triple, or even quadruple date-codes stamped onto them.Steven Snyder.

These additional codes were added by the retail stores - that's why they were not uniform. For example, situations that the pipes were not sold in the same year of production, it was a way to establish a new warranty period. In cases where the customer requested an F/T stem (for example) or some minor cosmetic issue was found, the pipe returned to the factory and, in some cases, received a new coverage date. In these situations the extra date-code is uniform.

It might have been added by the point-of-sales (shop, when the pipe was actually sold, so the guarantee period was easier to identify.Hener, K. S., Product Line Director - The White Spot Smoker's Accessory Division and Walthamstow site.

Prior to 1922 Dunhill marketed some 'seconds' or as termed by the company "faIlings" under the Dunhill brand name. Final examination in the Dunhill production process came after stamping and finishing and it appears from one example seen that pipes failing that examination were stamped with a large distinctive "X" over the DUNHILL stamping and then sold in the shop at a discount. From another example seen it appears that pipes 'dinged' at the Duke Street shop or otherwise selected for the price reduction were stamped "DAMAGED PRICE [followed by the reduced price]" on an otherwise empty unstamped area of the pipe, i.e. the bottom of the shank on a Bruyere. In fact, the very pipe that is often considered the first Dunhill ultimately became a 'second'. This was the 'windshield' pipe that Alfred Dunhill had manufactured in 1905. When that pipe proved less then a success Dunhill had the distinctive 'windshield' cut off and sold the recut pieces at a discounted price.

Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

Up to 1920 Dunhill had its bowls cut for it in Saint-Claude, France. The grading after the bowl turning process is where many a flaw is spotted and as long as the bowl turning was done in Saint-Claude Dunhill was able to leave the 'failings' behind and had only to deal with those flawed pieces that cropped up in the oil treatment, carving, and finishing process. Thus while as late as 1919 Dunhill considered introducing a 'seconds' line that would have been called the Red Spot pipe, the 'failings' were not significant enough to warrant such a course. However, when Dunhill began turning it's own bowls in 1920 with the consequent substantial 'failings' it had little choice but to form, as it did Alfred Dunhill did not believe in waste and similar to the above, during its the first decade Dunhill also offered a reduced price, ever-changing My Mixture blend #75 which consisted of all the leftover tobacco from custom blending mixed together. in 1922, the Parker Pipe Company to finish and market those 'failings'.· It appears that with the formation of Parker Dunhill ended the marketing of any seconds, as such, bearing the Dunhill brand.

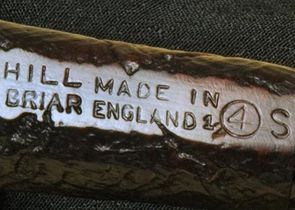

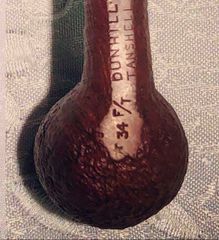

- Courtesy Nicolas Gutierrez

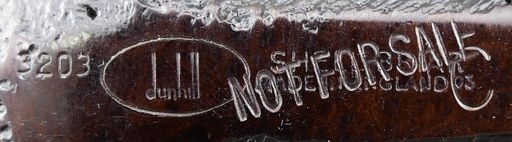

Here we have many variables, we need to observe the whole scenario because it depends on where it is graphed. For example, the "C" can indicate the model, a "Churchwarden" - if it is aligned with the pipe style (but it is not in use anymore nowadays - see more about it here Dunhill Shapes). It also can be the "C" for classification of the series "OD" or the series "D.R". It can be a "complementary", in this case, they were over-stamped "not for sale" in addition to the letter. Because it was a courtesy, they usually were not dated not to delimit the warranty period. There is also the "C" of "compliments", destined to British royalty.

C stands for “complementary”. Pipes stamped as such are usually pipe given to business partners as a complementary present and are not for sale. That is why they are additionally stamped with NOT FOR SALE, so they are not be re-sold and marked as such.Hener, K. S., Product Line Director - The White Spot Smoker's Accessory Division and Walthamstow site.

From the 1920s through the 1960s a "C" was used in the shaped stamping preceding the shape number to signify a churchwarden. Pipes of that period with churchwarden stems but no "C" in the shape nomenclature can be suspected of having a churchwarden bit later fitted to a pipe not initially intended to be a churchwarden.Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

Let's see some examples:

Today

Another atypical marking, a small square.

We checked our stamp registers, the small square is not registered as a factory stamp. We can only assume that it is an after-factory stamp; possibly it was added by the point-of-sale, but we have no knowledge of this.Hener, K. S., Product Line Director - The White Spot Smoker's Accessory Division and Walthamstow site.

Early days

I have seen subscript square stops on DRs dating from the 1910s to 1922 stamped either before or after DUKE ST S.W. or LONDON. Other then the subscript stop noted with respect to a Root DR I have seen no such markings in connection with the root finish. However, I have seen a subscript square in 1931 and 1937 Shells following the shape/category stampings. Likewise, a square subscript stop has been found on a late '30s DR immediately following the "DRR" stamping (which is stamped where the "A" would normally be found on a Bruyere). I have found no information as to the rationale for these seemingly random circles, stops, and numbers, but since there is nothing else random about the Dunhill nomenclature I strongly suspect that these ancillary stamps, in fact, began as uptick work/quality/pricing codes.

Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

On Pipephil we have this information: The little squares are typical to older DR stampings. Their meaning is not established but may be related to pricing categories.

But Loring considered this in one of his articles:

Information not reported here strongly indicates that while stop stampings continued after the early 1930s for Root DRs and into the post-WWII period, both the placement of stops and grade system changed dramatically. In light of some inquiries and loose remarks on eBay, it should also be noted that while one often sees stop stampings with standard Bruyeres (i.e. non DRs) of the 1910s and 1920s before either an A or a circled (A) there is no indication from the catalogs that these stops were value indicators. Undoubtedly whether a standard Bruyere pipe during this period was stamped with a circled or uncircled A or followed by a stop was meaningful, but that meaning most probably related to production or distribution concerns as opposed to grading or value.Loring, Grading the Pre World War II Dunhill Bruyere DR.

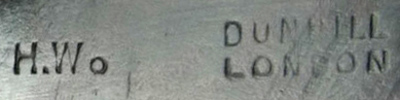

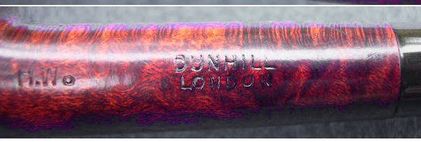

From the beginning of the 20s (perhaps 1923, when - according to some, Dunhill began to fully fabricate its pieces) by the end of the 30s, some pipes were completely manufactured, i.e, without any kind of automation. These pieces received the following marking on the shank: "H.Wo", referring to Hand Worked. The Carved Heads and D.Rs, which were also hand-crafted, however, were within another classification and did not receive this marking. In the Carved Heads case, they were "OD " from pre-WWII.

"H.W" was another pre-war stamping and meant 'Hand Worked'. This stamp was used, sometimes in conjunction with subscript square stops, to identify hand carved versions of standard, machine carved, shapes. An "HW" stamping was not necessarily indicative of higher pricing.Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

- Note: HT(Hand-Turned) is currently used instead of H.Wo, but the concept is the same.

There are additional stamps that are unknown even by the factory manager. Since there are no official records in the company's memos, perhaps they are unofficial extra stamps developed by authorized sellers for internal controls, to keep track of any pipe they sold that might ever be returned for some issue or by a collector to mark his pipes. Who knows? Without some kind of confirmation, it will remain a mystery.

Some sparse information suggests that these stamps have been added for repair control, such as stem replacement or structural repairs. But the production director refutes that hypothesis:

We did and still do often structural repairs like cracked stems and plug bowls (if possible) and those repairs are simply amazing. And no, we don't add any stamp. In case we are replacing a broken stem/shank we replicate the original stampings that were on the pipe before to keep it as original as possible.Hener, K. S., Product Line Director - The White Spot Smoker's Accessory Division and Walthamstow site.

Next, we will see three examples that the manufacturer does not recognize:

"SECONDARY STAMPINGS. Secondary light randomly placed stampings have been found on some pipes dating from the late '40s to the mid-'50s. The stampings include for instance "-11", "811-" and "B52". The meaning of these stampings is not presently known but one can speculate from the light random placement nature of the stampings and the absence of the same from the factory stamping log that they are post-production marks related to distribution and marketing.

RESTAMPING. Occasionally, when a pipe was sent to Dunhill for repair, parts of the nomenclature that were worn were restamped. In addition Dunhill has on occasion restamped worn nomenclature on otherwise healthy pipes. This restamping can sometimes be spotted when the stamping tools used do not match the style of the original nomenclature. In addition, it can be suspected when there are signs of double (i.e. over) strikes. On the other hand, such double strikes may also occur at the time of production when the first strike was deemed too weak." Loring, J. C., The Dunhill Briar Pipe, The Patent Years and After (self-published, Chicago, 1998).

Over my 45 years of collecting Dunhill pipe - I have seen these odd markings. I am of the opinion that they are marks put on by dealers. For instance, I saw a DRR from the 1930s that had a small H sideways. I have seen small letters placed in odd places on the shanks. I spoke to Dunhill long before the current management was on board and they were of the opinion that they were ‘after markings’. All Dunhill nomenclature has a meaning - price, shape and date.Richard Esserman - 2019.

From the very early days and up until the early 1970s (possibly 1974. This was soon to be replaced by a more detailed formal 4- and 5-digit system around 1976), Dunhill used a 6 as a prefix to the shape code to indicate that the pipe was made with a saddle-bit stem. For example, a Shape R indicates a pot-shaped bowl with a tapered stem, and a 6R would be the same bowl but with a saddle-bit stem, or 660, 639, and so forth.