Materials and Construction

The material and shape of a pipe has a profound influence upon the aesthetics and smoking qualities. Tobacco pipes come in many shapes and styles.

The basis for this section is from the Wikipedia entry Smoking Pipe (tobacco).

For an excellent overview of these shapes see Pipe Shapes by Bill Burney.

A comprehensive list of pipe maker material and suppliers can be found here: Materials and Supplies.

Parts Nomenclature

Bill Burney and A.S.P. have kindly permitted us to use the A.S.P. Pipe Parts Charts showing the parts and nomenclature of the pipe:

- A.S.P. Pipe Parts Charts, by Bill Burney, Copyright 2003-2011 (used by permission; all rights reserved)

Materials

Briar

→ Main article: Briar

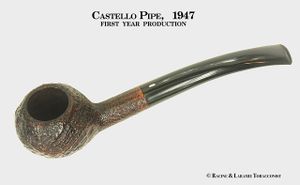

The majority of pipes sold today, whether hand made or machine made, are fashioned from briar.

Briar is a particularly good wood for pipe making for a number of reasons. The first and most important is its natural resistance to fire. The second is its inherent ability to absorb moisture. The burl absorbs water in nature to supply the tree in the dry times and likewise will absorb the moisture that is a byproduct of combustion.

Briar is cut from the root burl of the heath tree (Erica arborea), which is native to the rocky and sandy soils of the Mediterranean region.

Briar burls are cut into two types of blocks; ebauchon and plateaux. Ebauchon is taken from the heart of the burl while plateaux is taken from the outer part of the burl. While both types of blocks can produce pipes of the highest quality, most artisan pipe makers prefer to use plateaux because of its superior graining.

Alternative Woods Used For Pipemaking

Although briar pipes are by far the most popular, various other woods are also used by pipe makers (one example would be cherry wood). Click on one of the many wood types for examples of pipes made with these woods. Many thanks to pipemaker Elie for suggesting this section.

- African Blackwood or Mpingo | Link to Wikipedia on African Blackwood/Mpingo.

- Argentine Brown Ebony (Guayacaú Negro) | Link to Wikipedia on Guayacaú Negro

- Cherry Wood | Link to Wikipedia on Cherry Wood.

- Coihue | Link to Wikipedia on Coihue.

- Coronilla | Link to Wikipedia on Coronilla in pipemaking.

- Eucalyptus | Link to Wikipedia on Eucalyptus.

- Juniper | Link to Wikipedia on Juniper.

- Leadwood | Link to Wikipedia on Leadwood.

- Lemonwood | Link to Wikipedia on Lemonwood.

- Lenga | Link to Wikipedia on Lenga.

- Manzanita | Link to Wikipedia on Manzanita.

- Morta (Fossilized or Bog Oak) | Link to Wikipedia on Morta

- Mountain Laurel/Calico Bush | Link to Wikipedia on Mountain Laurel

- Olive Wood | Link to Wikipedia on Olive Wood.

- Osage Orange | Link to Wikipedia on Osage Orange.

- Pear Wood | Link to Wikipedia on Pear.

- Strawberry Wood | Link to Wikipedia on Strawberry Wood.

- Tagua Nut | Link to Wikipedia on Tagua Nut.

- Walnut | Link to Wikipedia on Walnut.

Also see

- Pipes in Other Woods an article written for The Collector by Tim Fuller

- Vecchie tradizioni contadine

- Other Materials

Meerschaum

→ Main article: Meerschaum

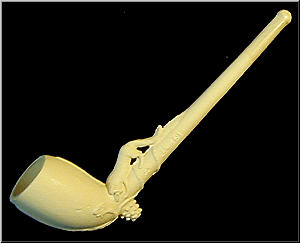

Meerschaum (hydrated magnesium silicate)[1], a mineral found in small shallow deposits mainly around the city of Eskişehir in central Turkey, is prized for its plasticity which allows it to be carved into many decorative and figural shapes. It was used as early as the 17th century in Turkey in the production of various utilitarian articles, but the first use as a pipe was not earlier than, according to translated documents, about 1725-1750. Along with clay, meerschaum represented the other common medium for pipes before the introduction of briar as the material of choice in the mid-19th century.

The word "Meerschaum" means "sea foam" in German, alluding to its natural white color and its surprisingly low weight. Meerschaum is a very porous mineral that absorbs elements of the tobacco during the smoking process, and gradually changes color to a golden brown. Old, well-smoked meerschaum pipes are prized for their distinctive coloring.

In selecting a meerschaum pipe it is advisable to determine if the pipe is indeed carved from a block of meerschaum, and is not made from meerschaum dust collected after carving and mixed with an emulsifier then pressed into a pipe shape. These products are not absorbent, do not color, and lack the smoking quality of the block carved pipe. It is not always obvious. Some collectors believe that some pipes marked "solid block meerschaum" may not be genuine. With no uniform grading authority, it is difficult to be sure in the case of an unknown maker, unless you are purchasing it from a trusted, well informed tobacconist. Be wary of inexpensive pipes from untrusted sources. Also look for the quality of the carving. Better carvers are unlikely to waste time carving composite meerschaum.

Morta

→ Main article: Morta

Morta, also known as Bog Oak or Abonos, is another form of wood used to make tobacco pipes. This wood, however, has been preserved by being buried in peat bogs, sometimes for hundreds of years or more. The material represents the early stages of wood's fossilization, and as a result the material is nearly 12% mineral in content, making it highly resistant to burnout. It is also praised for a neutral taste caused by the removal of all tannins, resins and the like from the wood during its long period of submersion.

Clay

→ Main article: Clay

The topic of clay pipes is very extensive. Therefore here only in a nutshell: clay in this case is almost always a very fine white clay. Low-quality "clay" pipes are actually made from porcelain forming techniques known as slip, and poured into a mold. These are porous, of very low quality, and impart unwanted flavors to a smoke. Top-notch clays, on the other hand are made in a labor-intensive process that requires beating all air out of the clay, hand-rolling each pipe before molding it, piercing with a fine wire, and careful firing. Traditionally, clay pipes are unglazed.

Clays burn "hot" in comparison to other types of pipes, so they are often difficult for most pipe-smokers to use. Their proponents claim that, unlike other materials, a well-made clay pipe gives a "pure" smoke, with no flavor addition from the pipe bowl. In addition to aficionados, reproductions of historical clay styles are used by some Historical re-enactors.

Clay pipes were once considered disposable items and the large quantities discarded in the past are often used as an aid in dating by industrial archaeologists.

Porcelain

→ Main article: Porcelain

The first type of porcelain produced by Johann Friedrich Böttger was a refined and extremely hard red stoneware known in Germany as Böttgersteinzeug. It retained very crisp definition in its cast and on applied details. The Böttgersteinzeug could be polished to a gloss before firing. Models were derived from Baroque silver shapes and Chinese ceramic examples. Meissen's production of a hard paste white porcelain that could be glazed and painted soon followed, and wares were put on the market in 1713. Multicolour enamelled painting was introduced by Johann Gregorius Höroldt in 1723, with an increasingly broad palette of colors that marked the beginning of the classic phase of Meissen Porcelain.

See Meissen Porcelain for additional information on Porcelain pipes.

Pipestone

The following excerpt is from Ben Rapaport's article, In Pipestone. A puzzling pipe of improvisational ingenuity.

Stone pipes have always been associated with the prehistoric peoples of North America. Specimens from as far back as 2,000 years ago have been encountered throughout the United States in argillite, pipestone, sandstone, soapstone and steatite. Pipestone is a hard, fine-grained, red clay, a type of argillite that ranges in color from mottled pink to brick red, and to rarer colors, such as mottled yellow, green, blue, brown, gray and black (steatite). And it is soft enough to file down with flint tools. It’s extremely durable, withstands intense heat, and doesn’t crack in the sunlight, so it can last for generations.

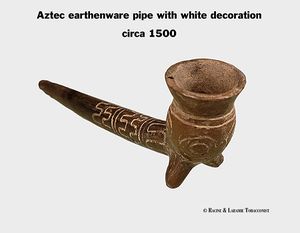

Aztec Ceramic

The article "Aztec Ceramic" first appeared on Smokingpipes.com here: The Mayans & Tobacco, November 9, 2018 by Chuck Stanion in Pipe Line and serves as an interesting introduction to the origins of this very interesting pipe recently acquired by Racine & Laramie Tobacconist.

Calabash

Calabash gourds (usually with meerschaum or porcelain bowls set inside them) have long made prized pipes, but they are labour-intensive and nowadays quite expensive. Because of this expense, pipes with bodies made of wood (usually mahogany) instead of gourd, but the same classic shape are sold as calabashes. Both wood and gourd pipes are functionally the same. They both have an air chamber beneath the bowl which serves to cool, dry, and mellow the smoke. There are also briar pipes being sold as calabashes. These typically do not have an air chamber and are named only because of their external shape.

The construction of a calabash pipe generally consists of a downward curve that ends with an upcurve where the bowl sits. This low center of gravity allows for the user to easily hold the pipe by the mouth alone, leaving his hands free. This advantage was often used by actors who wanted to depict their character smoking while permitting them to do other business simultaneously. That is why the character Sherlock Holmes, who never used this kind of pipe in the stories, is stereotypically depicted as favoring it because early dramatic productions, especially those starring William Gillette and Basil Rathbone, made this artistic decision. In fact, Holmes, who preferred very harsh tobacco, would probably have disliked the calabash because of the above-mentioned mellowing effect.

Gourds specifically intended for pipemaking are usually "hand trained" while they are still green & growing. Every few days, after the fruit has begun to develop, the grower will bend the "neck" of the gourd, until it has formed into a near semi-circle. These are mainly grown in South Africa.

Family: Cucurbitaceae (koo-ker-bih-TAY-see-ay); Genus: Lagenaria (lag-en-AR-ee-uh); Species: Siceraria (sy-ker-AR-ee-uh); Cultivar: Dipper(?)

Calabash Interpretations: Also popular with some collectors are Calabash shaped briar pipes, or Calabash interpretations. Fred Heim has written an interesting article on collecting these called Calabash, Calabash, Wherefore Art Thou Calabash?, The Genesis of a Collecting Motif By Fred Heim, with photography by Joe Harb.

Corncob

On the other end of the scale, "corncob" pipes made from maize cobs are cheap and effective, even if some regard them as inelegant. The cobs are first dried for two years. Then they are hollowed out to make a bowl shape. The bowls are dipped in a plaster-based mixture and varnished or lacquered on the outside. Shanks made from pine wood are then inserted into the bowls. The first and largest manufacturer of corncob pipes is Missouri Meerschaum, located in Washington, Missouri in the United States.[1]. Missouri Meerschaum has produced the pipes since 1869. General Douglas MacArthur and George Lincoln Rockwell were perhaps the most famous smokers of this type of pipe, along with the cartoon characters Popeye and Frosty the Snowman.

Corncob pipes remain popular today because they are inexpensive and require no "break-in" period like briar pipes. For these two reasons, corncob pipes are often recommended as a "Beginners pipe." But, their enjoyment is by no means limited to beginners. Corncob pipes are equally valued by both learners, and experienced smokers who simply desire a cool, clean smoke. Pipe smokers who wish to sample a wide variety of different tobaccos and blends also might keep a stock of corncobs on hand to permit them to try new flavors without "carryover" from an already-used pipe, or to keep a potentially bad tasting tobacco from adding its flavor to a more expensive or favored pipe.

For great additional information see:

- Missouri Meerschaum

- The Complete Corncob primer

- Missouri Meerschaum Corncob Buying Guide courtesy of John Patton (tiltjlp).

- Henry Tibbe

- Missouri Meerschaum Factory Tour

Metal Pipes

Metal pipes often incorporate means of trapping moisture that can cool the smoke before it reaches the mouth. Some say this can reduce the "Bite" and make smoking more enjoyable. Kirsten and Falcon pipes are still in production and deliver an excellent smoke. Beware though, there are many different metal pipes out there, of varing styles and brands, and collecting them can be very addictive.

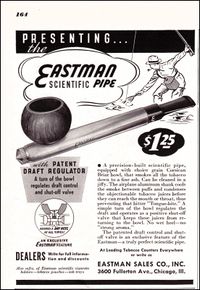

Eastman Pipe - By Eastman Scientific. Not sure how long these were in production, or any of the details with the exception of the flyer. If you have additional information, please click on the blue link and add the information into an article for us.

Plumb - Marked Plumb on the shank and stem and Peacemaker England on the bottom. Briar changeable bowl. Need information!

Sweetheart - Looks similar to Kirsten, but is a separate company that was located in St.Paul Minnesota.

Bryson - Another Metal pipe with briar bowl, circa 1947.

An excellent website devoted to metal pipes: Smoking Metal. Includes various Falcon aluminum-stem pipes, plus Kirsten, Yello Bole, Dr. Grabow (Viking) and many others.

An interesting book on the subject: Back From The Ashes, Uncovering The Lost History Of G. L. Hunt and the Falcon Pipe, by K. A. Worth ~ Winner, 2008 Illinois Historical Society Book Award. Available from the author: Worthy Works Press and $2.99 Color eBook (Updated and Expanded for 2012) at: Amazon.com. For more info. see Books/Publications page...

Build your own custom Kirsten Metal Pipe at Kirsten Pipe Company

Kirsten Pipe Company - An article by Dave Whitney

The pipe (pyrolytic graphite/phenolic resin)

→ Main article: The pipe

In 1963, Super-Temp Corporation began making plastic pipes with pyrolytic graphite bowl liners. They were called the pipe. In 1965, Super-Temp contracted to market their unique pipes through Venturi, Inc., the company which sold Tar Gard cigarette filters. Colors and stripes began to be offered circa 1967. About 1970, THE SMOKE pipes were added to the line - they were non-traditional shapes with a less expensive bowl liner. Venturi pipes were added around 1972 - they had no liner in the bowls at all. The pipes were out of production by 1975.

See the excellent the pipe website by Billie W. Taylor II, Ph.D

Brylon (High Temperature Resin and Wood Flour)

In 1966, S.M. Frank developed a material called "Brylon" made of a high temperature resin combined with "wood flour", which is pulverized wood of varying consistency. The pipes were cheaper and more durable, but heavier in the mouth and had a tendency to smoke hot and wet. They are still made today, and favored by some for their inability to be burnt out or otherwise damaged without significant effort and the ease of cleaning the pipe. For more information see S.M. Frank.